Magnetic – Dielectric Nanocomposites

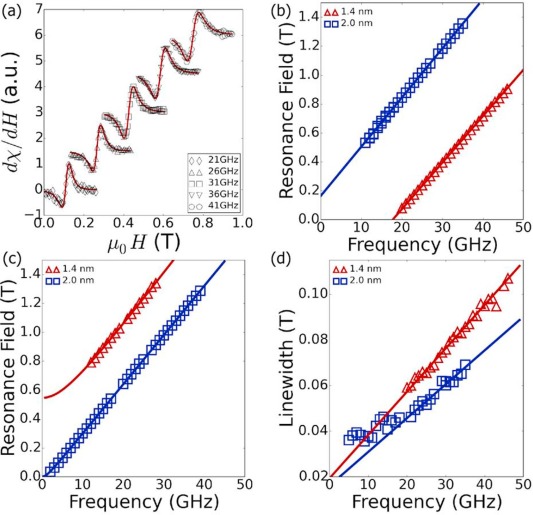

Magnetic Thin Films display interesting magnetic phenomena as a result of their dimensionality as well as possessing properties which allow their exploitation in a range of devices and applications. A major area of thin film technology is that of magnetic recording. Currently one of the most promising Perpendicular Magnetic Anisotropy (PMA) materials for MRAMS is composed of CoFeB/MgO/CoFeB stacks, the current magnetic tunnel Junction (MTJ) industry standard. The emergence of spin-orbit torque magnetic random access memory (SOT-MRAM) [6–9] is driving much of the research interest. These stacks show high tunnel magnetoresistance and a low threshold current for spin-transfer torque magnetization switching properties of particular importance for MRAM applications. Split CoFeB/Ta/CoFeB stacks grown directly onto high spin-orbit coupling W, demonstrated high interface anisotropy and potential for high spin-orbit coupling with high PMA.

A. Kaidatzis et al. “Investigation of split CoFeB/Ta/CoFeB/MgO stacks for magnetic memories applications”. J. Magn. Magn. Mat. 473, 355-359 (2019)

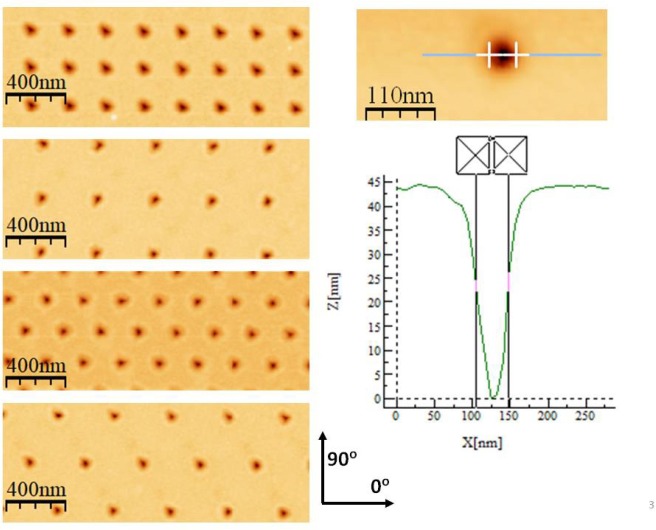

Another form of low dimensional materials whose properties may be taken advantage of is that of nanopatterned magnetic materials. Research carried out on Magnetic Antidot Arrays (MAAs) of Co/permalloy hard-soft bilayer show that that MAAs can provide an efficient way to tailor the magnetic properties of thin films; their magnetic coercivity, as well as in-plane anisotropy, by appropriate selection of the bilayer materials and MAA symmetry. For example a top-down approach using focused ion beam has been employed to fabricate Co/Permalloy hard-soft bilayer magnetic antidot arrays. These nanopatterned films were studied with particular emphasis on their magnetic coercivity. The antidots have a diameter of 40 nm and the studied antidot symmetries are square and hexagonal. A dependence of magnetic coercivity on the relative thicknesses of the magnetically hard (Co) and soft (Permalloy) layers is found; increasing Permalloy thickness results in lower magnetic coercivity. Furthermore, the long-range periodicity of top-down nanopatterned antidots results in higher magnetic coercivity and a stronger magnetic domain-wall pinning, compared to identical hard/soft bilayers of short-range order deposited on porous anodic alumina. The combination of antidot symmetry and hard/soft thickness, allow for efficient tailoring of the magnetic properties of nanopatterned thin films. Finally, magnetic force microscopy imaging of the antidot array magnetic configuration shows striking qualitative differences between the two array symmetries: square symmetry arrays have inhomogeneous magnetic state and a high density of immobile super-domain walls, whereas hexagonal symmetry arrays show a homogeneous magnetic configuration.

A. Kaidatzis et al. “Nanopatterned hard/soft bilayer magnetic antidot arrays with long-range periodicity”. J. Magn. Magn. Mat. 498, 166142 (2020).

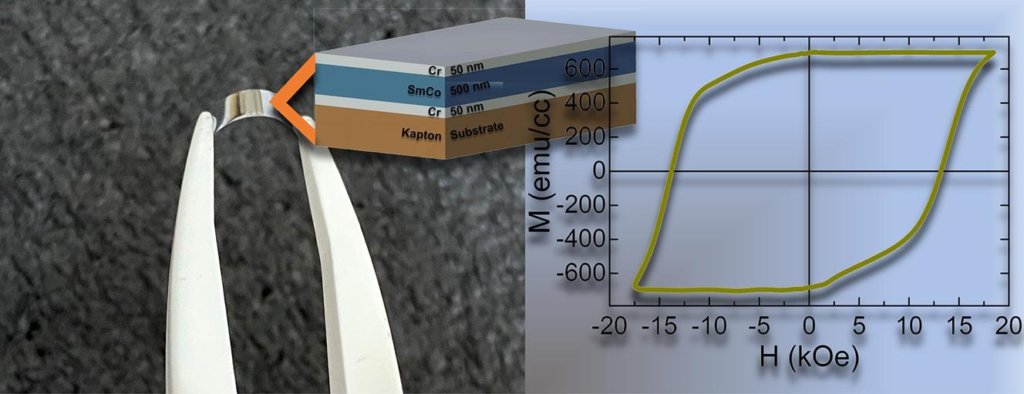

Integrated-circuit (IC) technologies for microelectromechanical systems (MEMS) demand continuous innovations for miniaturized electromechanical actuators, sensors, and micro-systems that are necessary for electric, mechanical, radiant, thermal, magnetic and chemical actuation and sensing. Magnetic MEMS based on permanent magnetic films, involve micron-sized motors, actuators, mini-pumps, and many other devices. This field has grown into a prosperous research and development area. Micro and nanodevices depend on non-conventional substrates that tend to receive considerable interest from the flexible-electronics market. Despite the fact that magnetic structures have been successively grown on flexible substrates for more than a decade, only recently fully functional magnetic device were achieved. Flexibility, stretchability, and rollability have become crucial for today’s applications such as biocompatible electronics that include wearable devices, flexible medical devices, epidermal devices, and implantable electronics.

A recent major success in the field of thin film magnetic fabrication is a world first in growing magnetron sputtered Sm-Co hard magnetic phases on a flexible substrate with coercive field up to 1.38 Tesla and an energy product of 16.9MGOe. These results lay the foundations for the design and fabrication of flexible magnetic devices.

Tzanis et al, “Micrometer thick Sm-Co films for applications on flexible systems”, Materials Science and Engineering B: Solid-State Materials for Advanced Technology, 280, Art 115691, (2022)