Graphene and Flexible

Graphene and Flexible

I. Graphene Oxide

Low-temperature thermal reduction

Low-temperature (≤300 °C) thermal treatment of graphene oxide (GO) and the role of low to moderate heating temperature to the evolution of the original functional groups anchored on the GO skeleton, has been closely investigated by Fourier transform infra-red (FT-IR) spectroscopy. The process lends itself to the production of conductive reduced GO with increased functionalities suitable for application in gas sensor and biosensor fabrication.

Graphene oxide gas sensors

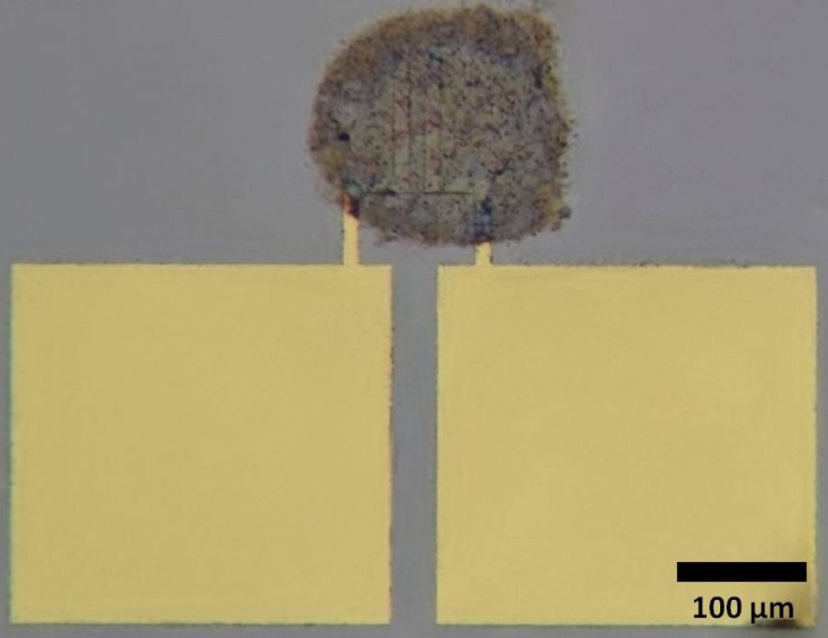

Simple graphene oxide gas sensors may be fabricated by drop-casting or by Laser Induced Forward Transfer (LIFT) in collaboration with NTUA between Au electrodes.

II. Flexible Graphene Nano Platelets / Polydimethylsiloxane Nanocomposite Strain Sensor

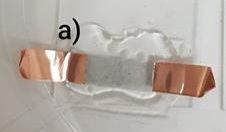

Carbon-based materials are commonly used as fillers in polymer matrices for the fabrication of flexible physical and chemical sensors. Amongst carbon materials, graphene has emerged as a promising next generation material replacing the traditionally used carbon black. In this work, we have developed a flexible graphene nanoplatelets/polydimethlylsiloxane (GNP/PDMS) resistive strain sensor with copper tape is used to conduct the GNP/PDMS composite.

III. Flexible Chemical Sensors

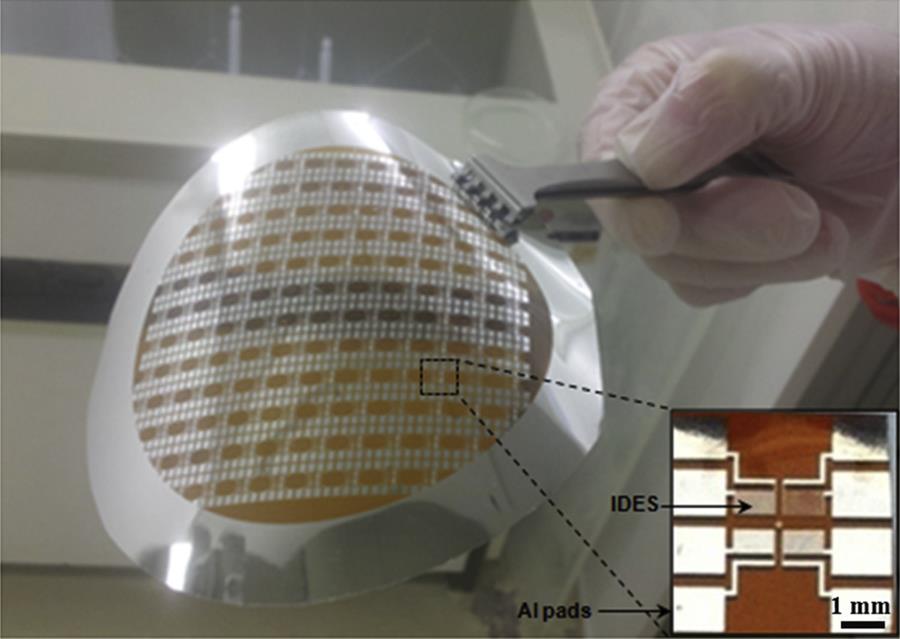

A versatile, two-step, lift-off method, for the fabrication of flexible capacitive chemical sensors based on interdigitated electrodes (IDEs) has been developed. A Polyimide (PI) foil whose one side is coated with a thin Aluminum (Al) film is used as the sensor substrate. Precise patterning of the sensor sensing layer, on the surface of the Al IDEs, is achieved using a two-step lift-off process which involves a first lift-off during which a Polyvinyl alcohol (PVA) film is spin-coated and patterned, followed by the deposition or spin coating of the sensing layer and a second lift-off to pattern it on the IDEs area and form the final sensor.

IV. PDMS GC Column

Gas and liquid chromatography is one of the most appropriate methods for chemical analysis. In this work, a gas chromatographic microcolumn made of polydimethylsiloxane (PDMS) was developed. This material is commonly used as stationary phase in GC large-scale systems, and in this system it serves both as structural material of the micro-column as well as the stationary phase enabling gas mixture separation by different absorption and desorption of the sample components on the column walls. Gas separation is demonstrated by means of a VOC sensor connected at the exit of the micro-column.