Thermo-mechanical properties of Ceramics and Composite Materials

The investigation of thermo-mechanical material properties is a central field of research of the CCM Group. This concerns the examination and assessment of archaeological or historical functional materials as well as the development and advancement of new materials adapted from ancient technologies. The thermo-mechanical performance of traditional materials depends on various intrinsic and extrinsic factors, such as the utilized raw materials, potentially mixed or tempered, design and forming of the objects or structures, processing applying for example heat and on the other hand environmental parameters affecting the deterioration.

Parameters affecting the thermo-mechanical performance

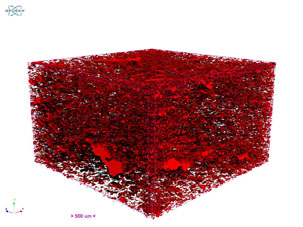

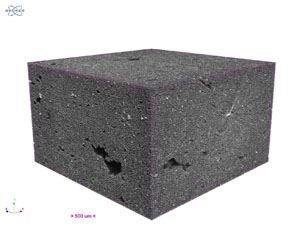

The intrinsic parameters are determined by compositional examination through elemental and mineralogical analysis as well as micro-structural examination, using optical and scanning electron microscopy and porosimetry. Furthermore, μCT is tested in collaboration with external partners with the scope to achieve a full 3D image of the microstructure.

μCT Scan of an amphora fragment (voxel size 4 μm3): Greyscale 3d rendering (left) and pore structure (right) (Micro X-ray Lab, Bari, Italy)

In order to understand how ancient or traditional craftspeople were adapting their products to specific functions and applications either actual specimens of these products are tested for their material properties or series of replicated specimens, varying parameters, such as process temperature or type and amount of additives. In terms of mechanical performance following properties are studied on a regular basis:

- compressive strength

- flexural strength

- toughness

- impact strength

- Young's modulus

Flexural strength and toughness are tested for example in 3-point-bending tests of bar shaped specimens or in bi-axial flexure tests of disk shaped specimens with spherical indenter. The thermal properties, which are assessed comprise:

- Thermal conductivity

- Heat capacity

- Thermal diffusivity

- TGA

- Thermal shock resistance

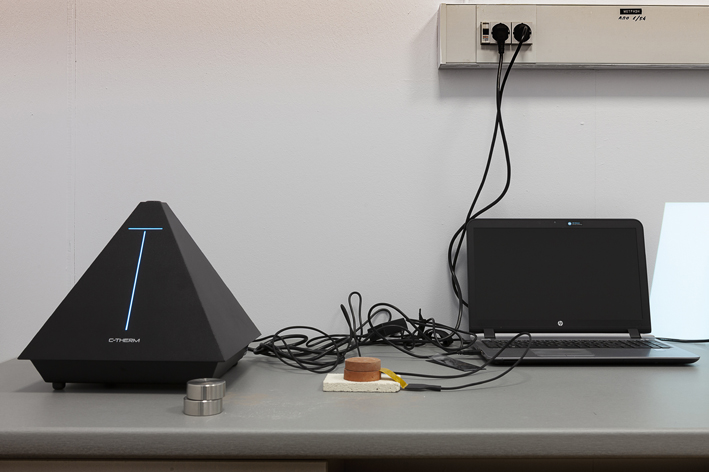

Heat transfer properties are determined in stationary tests with a guarded hot plate setup as well as dynamically with a transient plane source (TPS) setup, which provides apart from thermal conductivity also heat capacity and thermal diffusivity.

Examining heat transfer of ceramic disks: Guarded hot plate (left), Transient plane source (right)

Publications

Hein, A., Müller, N.S., Day, P.M., Kilikoglou, V., Thermal conductivity of archaeological ceramics: Impact of inclusions, porosity and firing temperatures, Thermochimica Acta 480 (2008) 35-42. DOI: 10.1016/j.tca.2008.09.012

Hein, A., Karatasios, I., Müller, N.S., Kilikoglou, V., Heat transfer properties of pyrotechnical ceramics used in ancient metallurgy, Thermochimica Acta 573, 10 (2013) 87–94. DOI: 10.1016/j.tca.2013.09.024

Hein, A., Vekinis, G., Kilikoglou, V., Modeling of biaxial flexure tests of transport amphorae with the finite element method: Fracture Strength, Deformation and Stress Distribution, forthcoming.

Kilikoglou, V., Vekinis, G., Maniatis, Y., Day, P.M., Mechanical performance of quartz-tempered ceramics: part I: strength and toughness. Archaeometry 40 (1998) 261-279. DOI: 10.1111/j.1475-4754.1998.tb00837.x

Müller, N.S., Kilikoglou, V., Day, P.M., Vekinis, G., The influence of temper shape on the mechanical properties of archaeological ceramics, Journal of the European Ceramic Society 30 (2010) 2457–2465. DOI: 10.1016/j.jeurceramsoc.2010.04.039

Müller, N.S., Vekinis, G., Day, P.M., Kilikoglou, V., The influence of microstructure and texture on the mechanical properties of rock tempered archaeological ceramics, Journal of the European Ceramic Society 35 (2015) 831–843. DOI: 10.1016/j.jeurceramsoc.2014.09.025

Tite, M.S., Kilikoglou, V., Vekinis, G., Strength, toughness and thermal shock resistance of ancient ceramics, and their influence on technological choice. Archaeometry 43 (3) (2001) 301–324. DOI: 10.1111/1475-4754.00019