LTE-TSM & TEM / Low Temperature Evaporator for Temperature Sensitive Materials and Thermal Evaporator for Metals

A low-temperature evaporator, used in deposition, operates by heating source materials to a relatively low temperature to produce vapor for thin-film coating processes, typically under vacuum conditions. The use of low temperature minimizes thermal damage to both the source material and the substrate, making it suitable for depositing heat-sensitive compounds such as organic materials and polymers. Once vaporized, the material travels through the vacuum chamber and condenses onto the substrate, forming a uniform thin film. This method is commonly used in applications like organic electronics, OLEDs, and certain semiconductor processes.

Tool

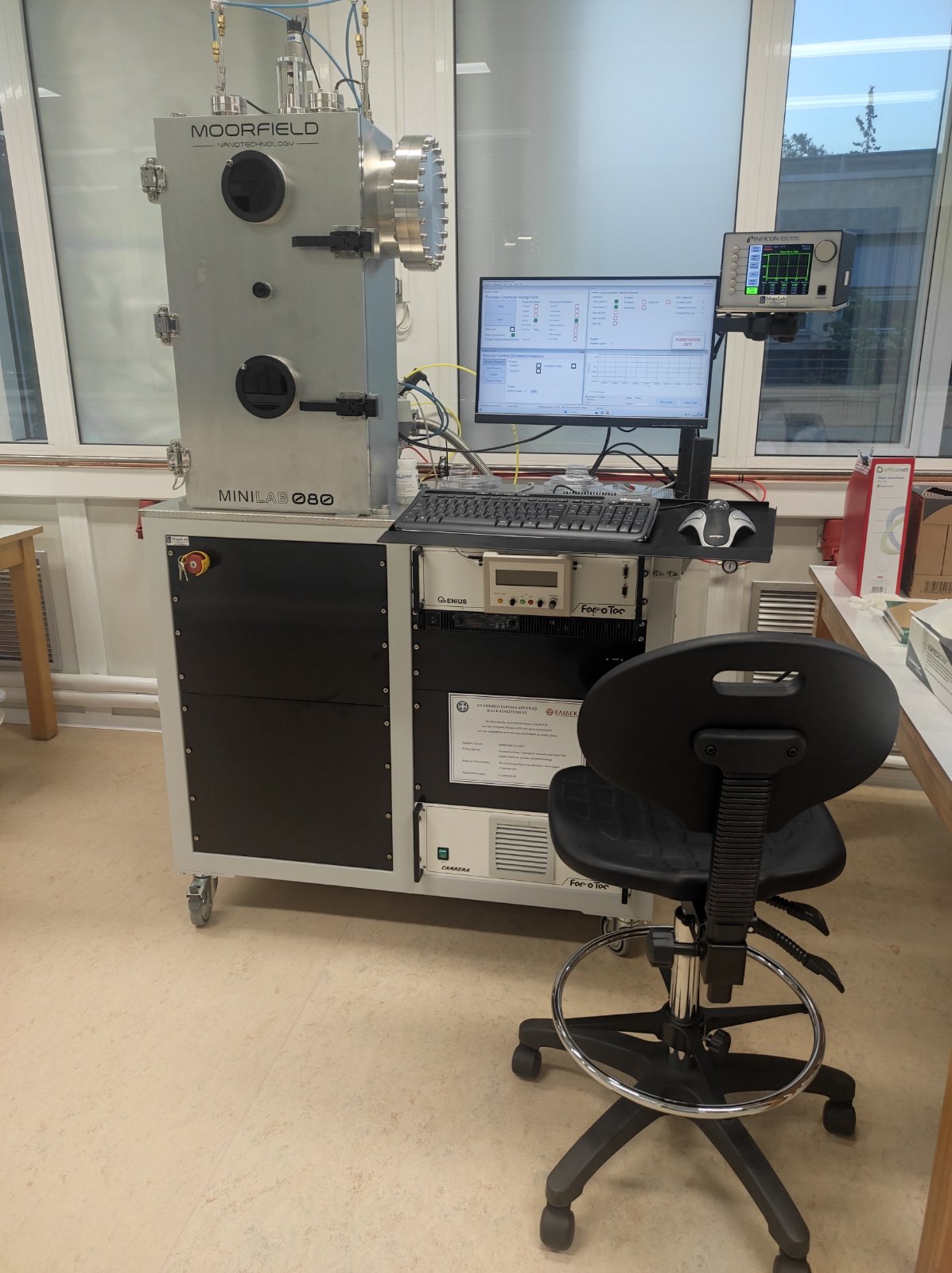

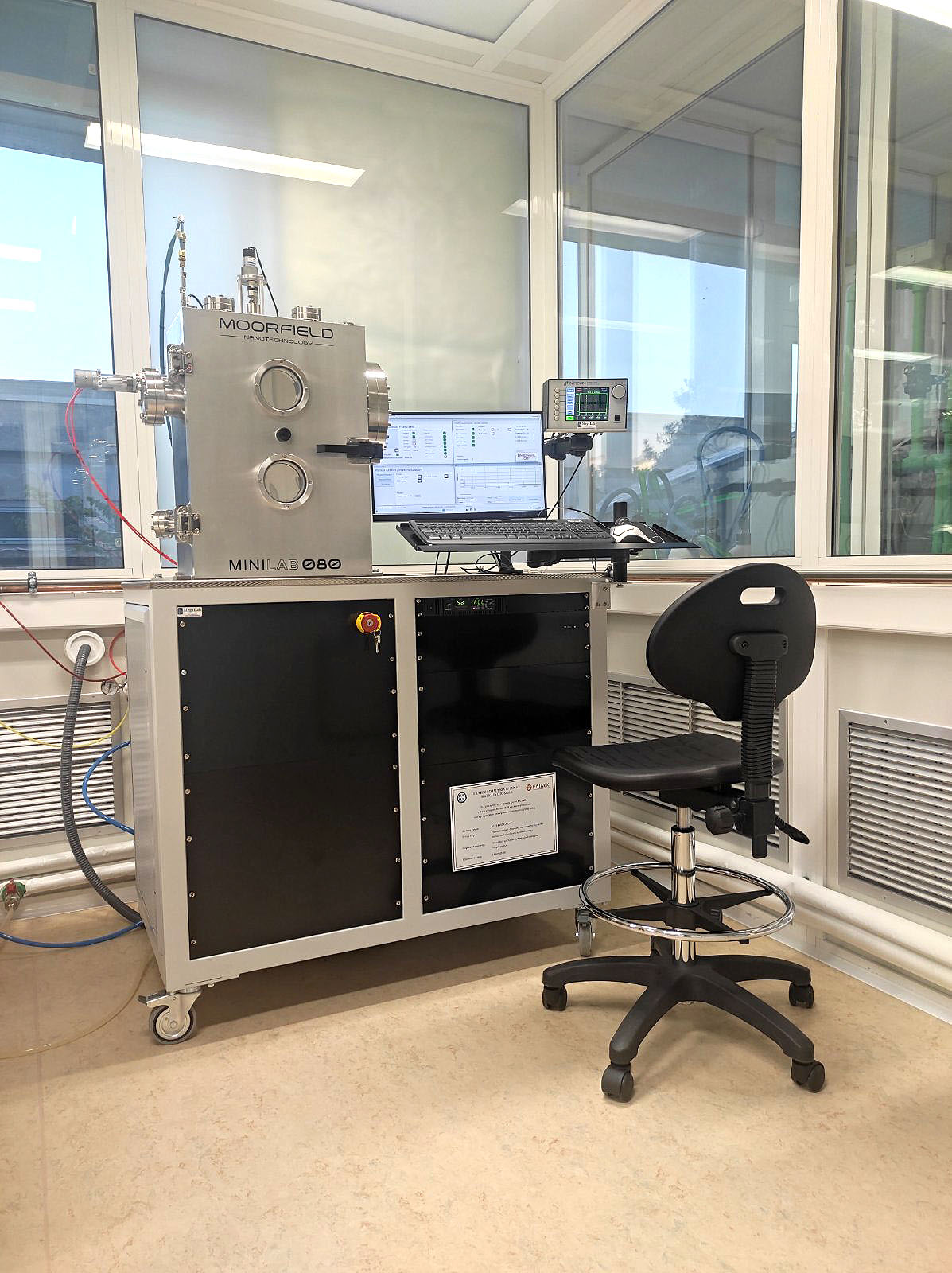

Minilab LT080A (Moorfield Nanotechnology

Method

Low-temperature evaporation and thermal evaporation

Process Parameters

Organic materials: Fullerenes, Teflon and other low-surface energy polymers or oligomers, C60.

Sulfides and other Compounds: MoS2, WS2, Sb2S3, Bi2S3, SnS2, ZnS, MoTe2, MoSe2.

Metals such as Al using a thermal evaporation source.

low-temperature evaporation source: up to 600 οC

thermal evaporation source: 100A/8V Substrates: Semiconductors, dielectrics, resists

Substrate Size

From small samples of 1x1 cm2 to 4΄΄ wafers

Applications

Organic coatings, organic electronics, OLEDs, organic photovoltaic cells (OPVs), metal contacts and interconnects.

Accessories / Thin Film Deposition Controller

SQC-310 (INFICON Instruments for Intelligent Control)

Manual mode: Measures the thickness of the film deposited on the wafer through quartz crystal microbalance (QCM) Automatic mode: Perform evaporations through recipes