“Smart” Multifunctional Surfaces

A. Wetting and optical property control

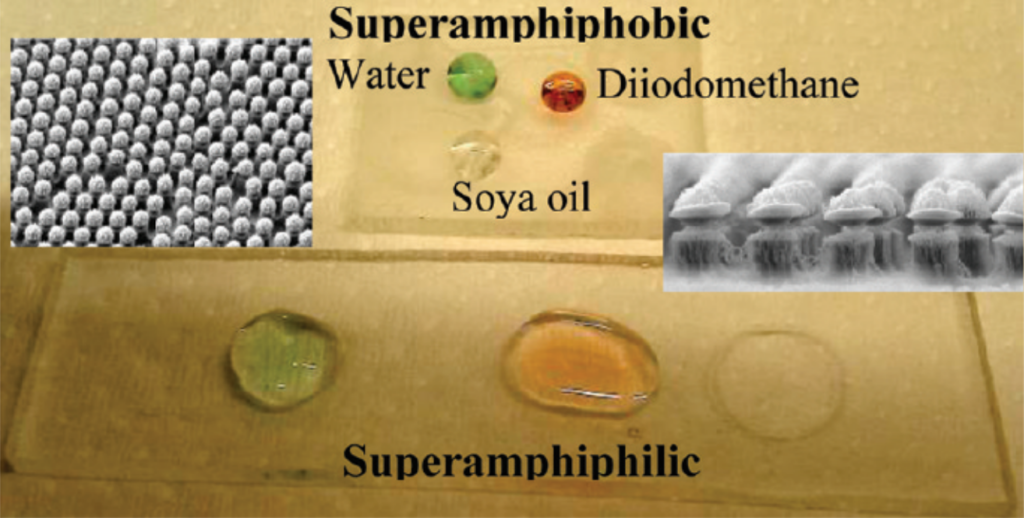

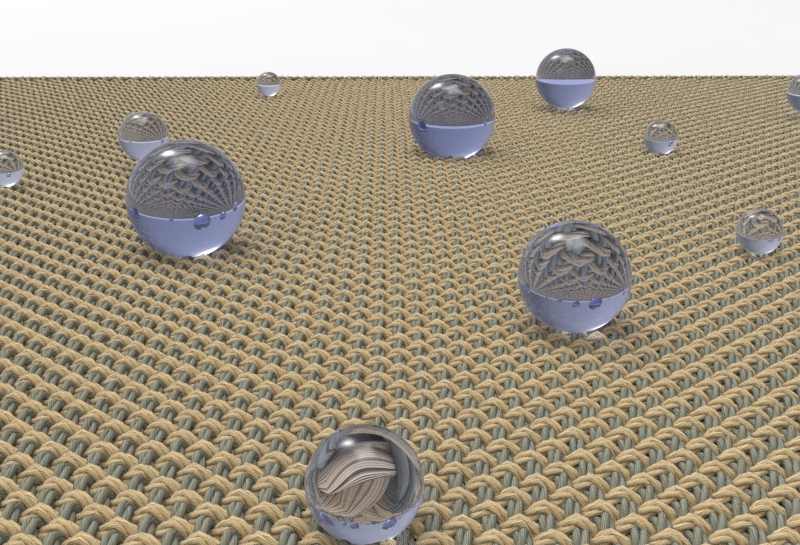

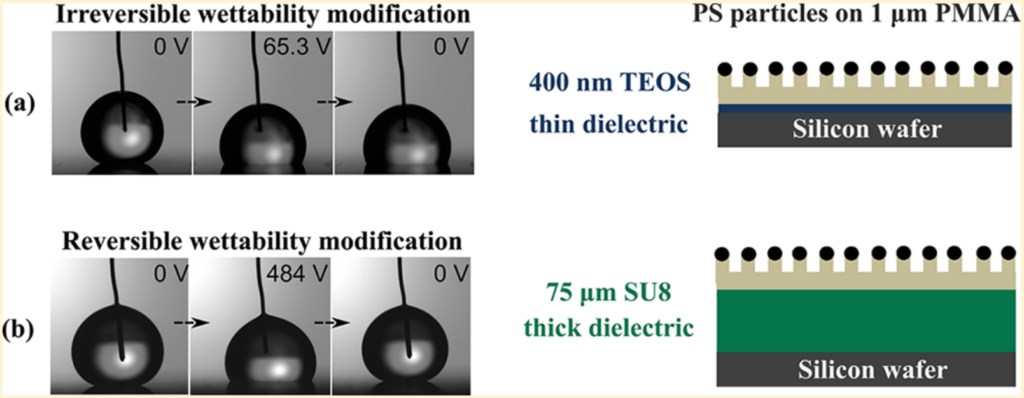

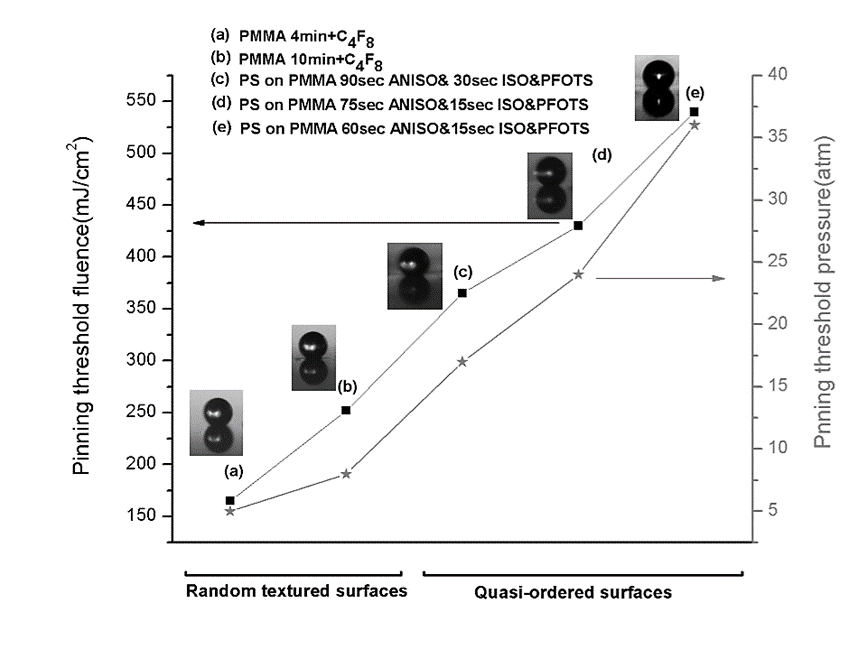

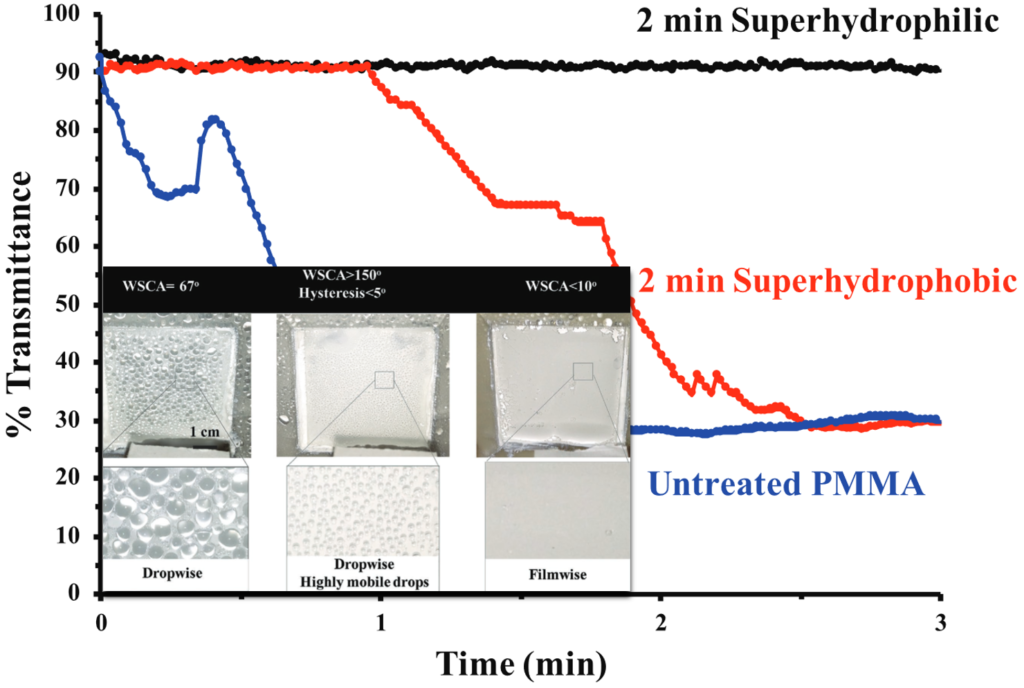

Our group has acquired expertise in wetting control of surfaces at its extremes namely superhydrophobic, superoleophobic, superamphiphobic, and superhydrophilic surfaces, focusing first on polymers. Using our plasma micro-nanotexturing technology, almost all polymers can be rendered superamphiphobic followed by a hydrophobic film deposition. Such surfaces have shown extreme durability on drop impact (up to 30 atm impact pressure). Moreover, we have demonstrated everlasting underwater durability of plasma nanotextured surfaces, and have also presented a new technique to monitor underwater superhydrophobicity. Since, such surfaces have been applied for reduced friction, showing almost an order of magnitude reduced static forces compared to simple hydrophobic surfaces, high expectations on the applicability for reducing friction during vessel motion have been raised. Moreover, nanotextured surfaces are good for optical applications such as antifogging surfaces, or transparent, antireflective and self-cleaning surfaces. Several examples are shown in below.

B. Biofunctionality control

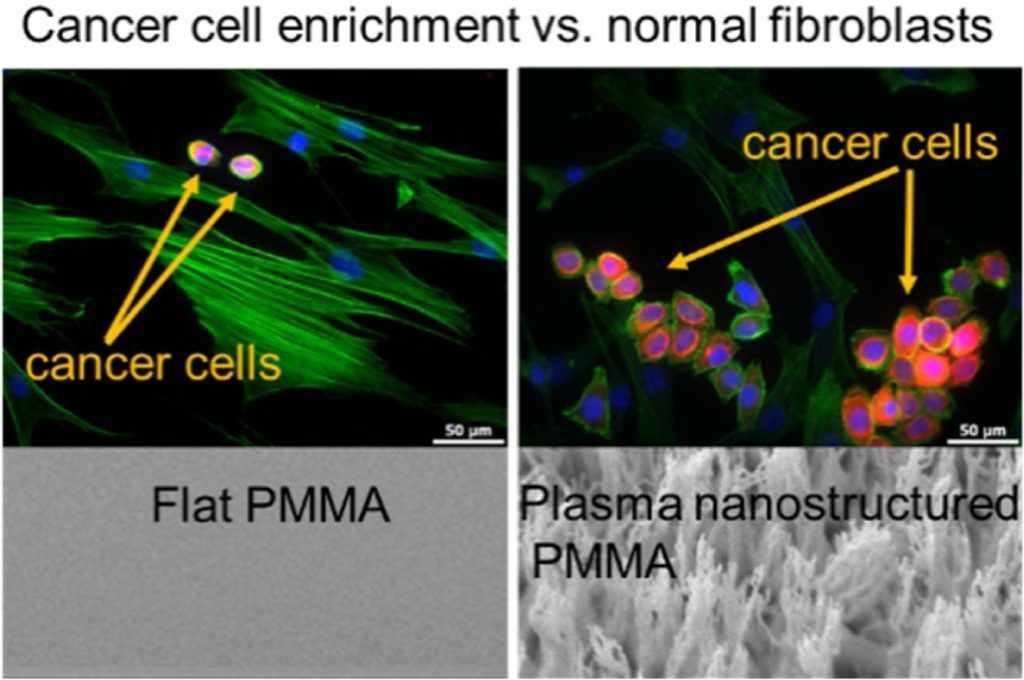

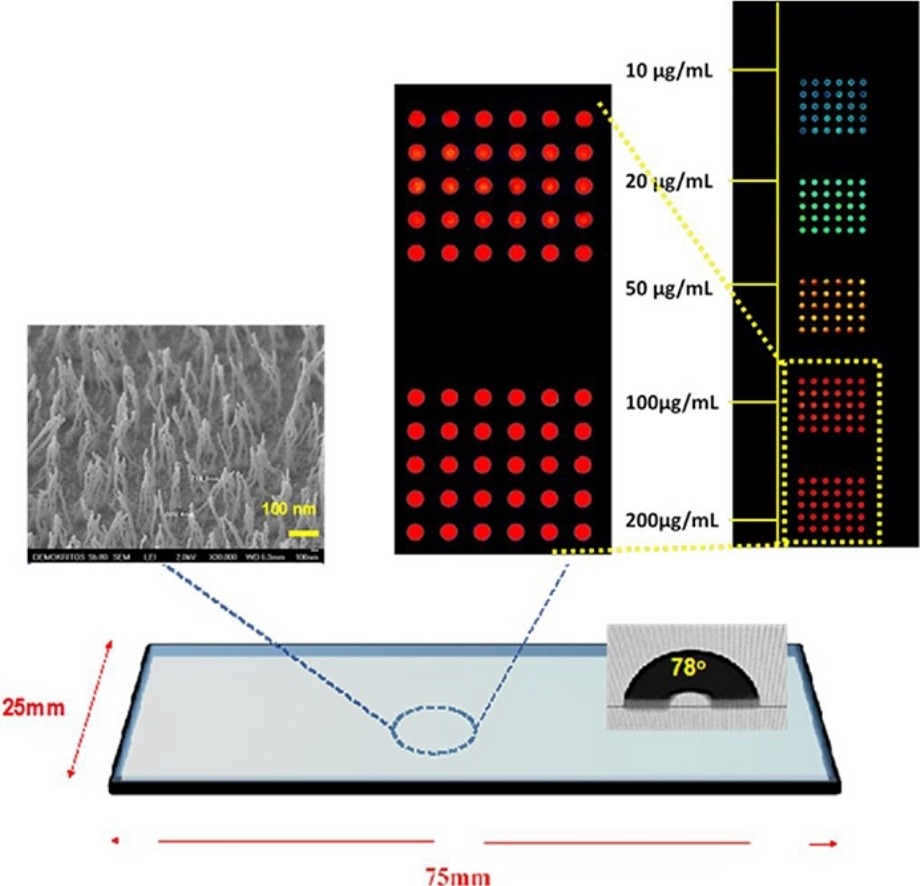

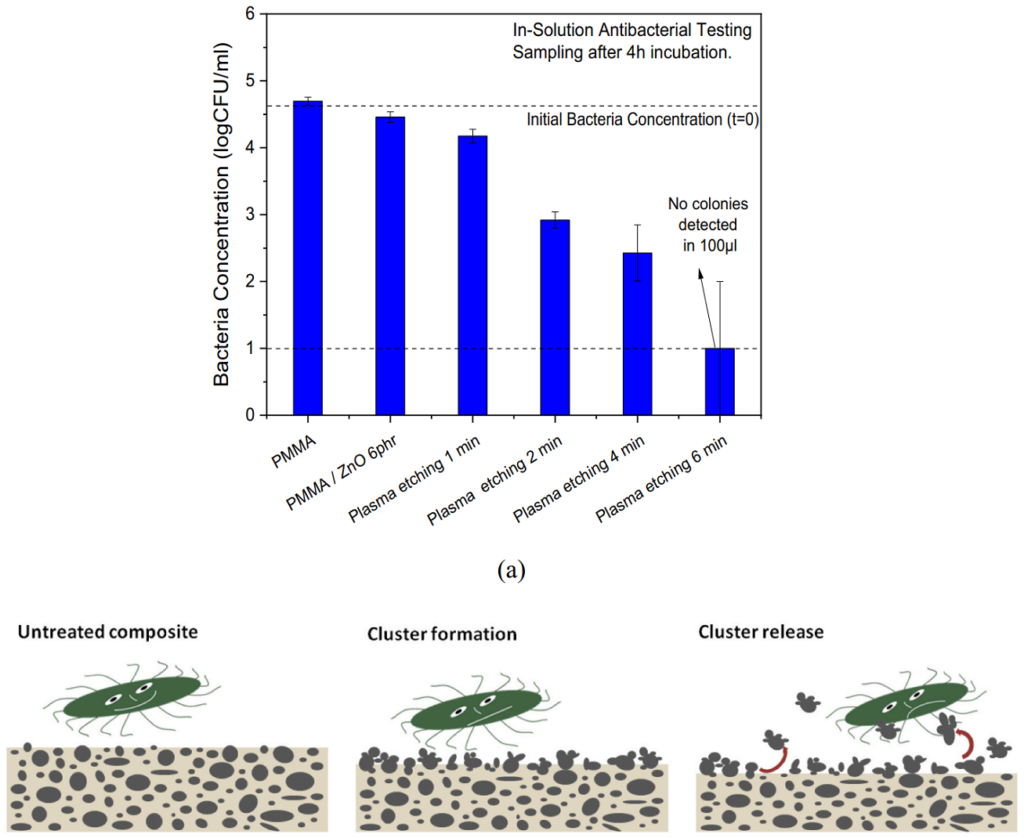

Our group has also pioneered the use of micro-nanotextured surfaces for covalent-like biomolecule attachment leading to high density microarrays, or sensitive sensors, and high binding capacity microfluidics for biomolecule and cell capture. This work has been patented and has been the core technology of our spin-out company Nanoplasmas p.c. which develops area selective, highly binding, biomolecule, and bacteria capturing devices, as well as DNA purification, and cancer cell enrichment surfaces. An additional application of these smart surfaces has been their use as antibacterial surfaces, with a double action, namely antisticking and bactericidal with both mechanical and chemical bactericidal effects. Recently, we have also started to use atmospheric pressure plasma etching of nanocomposite polymers, containing inorganic antibacterial nanomaterials. Plasma etching enriches the surface concentration of antibacterial agents and thus reduces the volume percent that is necessary for adequate antibacterial action. Finally, we have explored plasma nanotextured surfaces for cell adhesion, and we have discovered and patented the selective enrichment of cancer cells on such surfaces. This discovery is expected to be used for improving biopsies.

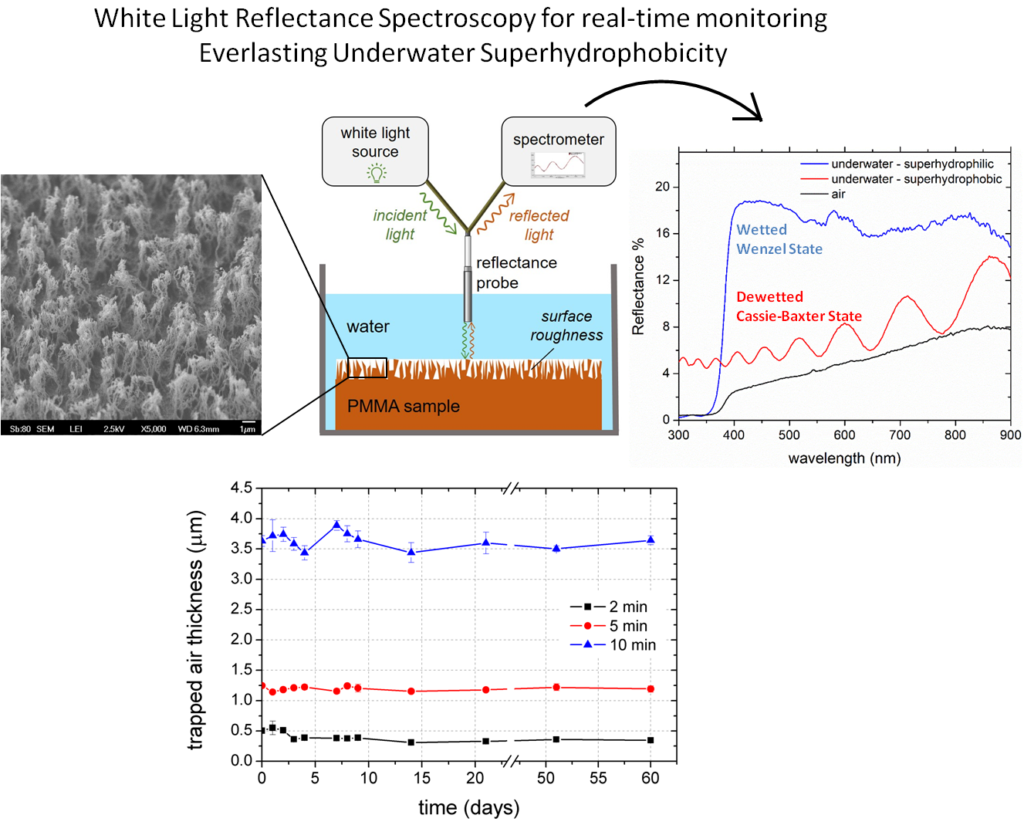

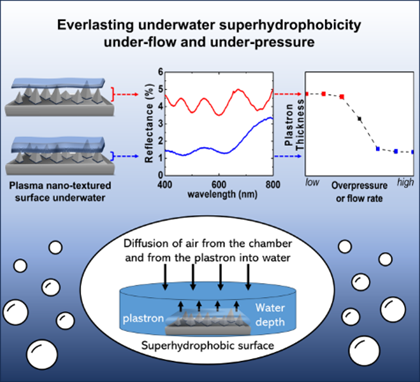

C. Extremely stable underwater superhydrophobicity via plasma micro-nanotexturing

Underwater superhydrophobic surfaces, inspired greatly by the leaves of Salvinia molesta plant, are expected to retain a stable underwater air layer, also known as plastron, that prevents wetting. However, this is rarely achieved under real-life conditions since external forces, including hydrostatic pressure or water flow, seriously affect the plastron lifetime, thereby delaying the usage of such coatings by the maritime industry. Using our technology we have managed to fabricate durable underwater superhydrophobic, plasma micro-nanotextured Poly(methyl methacrylate) (PMMA) surfaces against applied external overpressures of up to 1500 mbar under conditions where water is undersaturated in air, and against water flow rates of up to 350 ml min-1 (corresponding to a flow velocity of 6.5 mm/s), monitoring the plastron thickness using in-situ White Light Reflectance Spectroscopy (WLRS). We provided an in-depth explanation of the mechanisms related to the plastron lifetime of superhydrophobic surfaces, submerged in air-undersaturated water subjected to an overpressure, and argue that such an experiment is much more demanding than immersion of a surface to several meters in air-saturated water. We have shown how ‘everlasting’ underwater superhydrophobicity can be achieved under unsaturation conditions and demonstrate the endurance of superhydrophobic properties for overpressures equivalent to a 10-meter water depth for at least two weeks of continuous underwater experiments.

Method for the fabrication of periodic structures on polymers using plasma processes

Greek patent application 20080100404 – 13/06/2008, Patent grant No. 1006618

European patent application 09762028.0 – 15/06/2009, Patent grant No. EP2300214

USA Patent No. US8951428B2 - Method for the fabrication of periodic structures on polymers using plasma processes - Google Patents

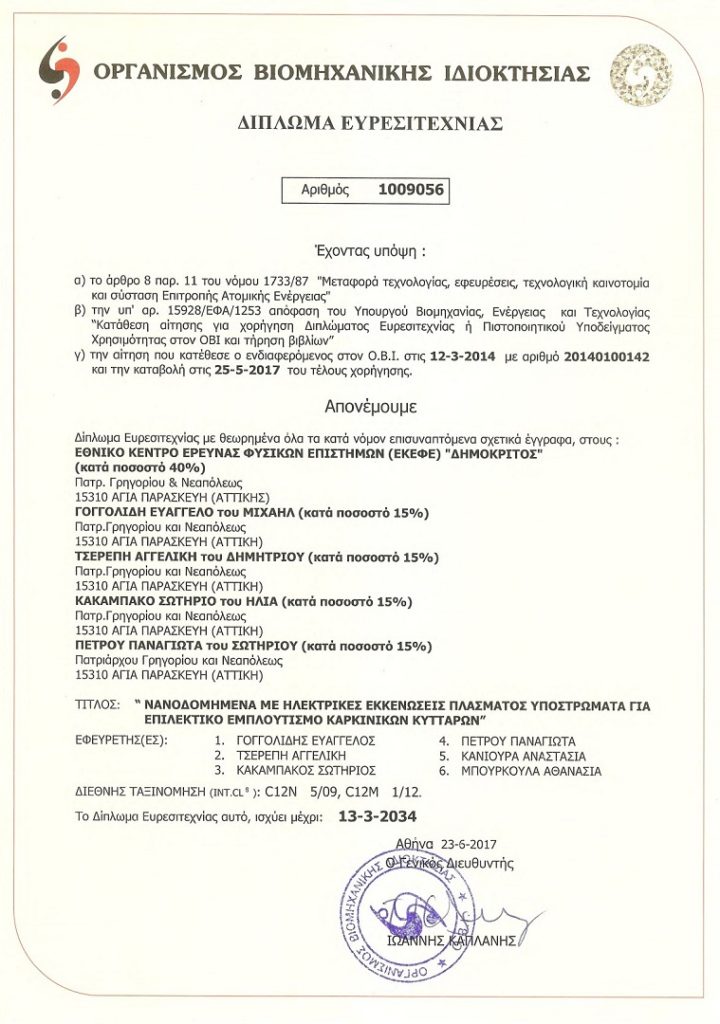

Gaseous Plasma nanotextured substrates for selective enrichment of cancer cells

Greek patent application 20140100142 – 12/03/2014, Patent grant No. 1009056

European patent application 15386007.7 – 12/03/2015, Patent grant No. EP2918675

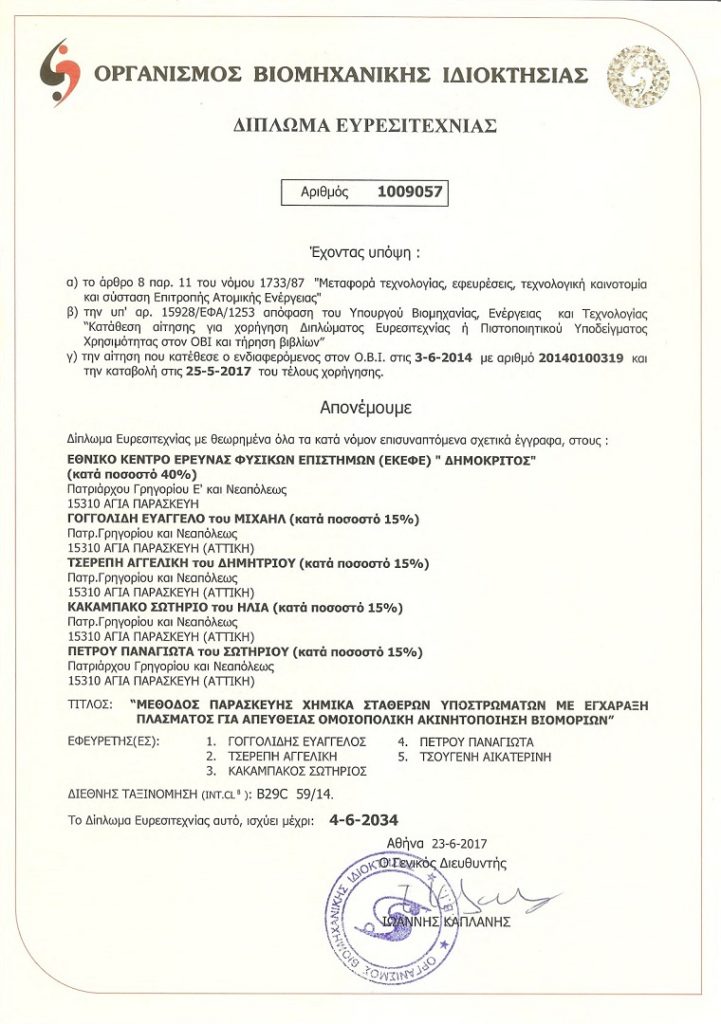

Method to fabricate chemically-stable plasma-etched substrates for direct covalent biomolecule immobilization

Greek patent application 20140100319 – 03/06/2014, Patent grant No. 1009057

European patent application 15386014.3 – 29/05/2015, Patent grant No. EP3284581