Process Analysis and Simulation

The research activity on analysis, modeling, and simulation addresses both processes and phenomena. Scientific and engineering problems are attacked with aim to illuminate physical mechanisms, reveal critical parameters, and achieve desired system/process behavior.

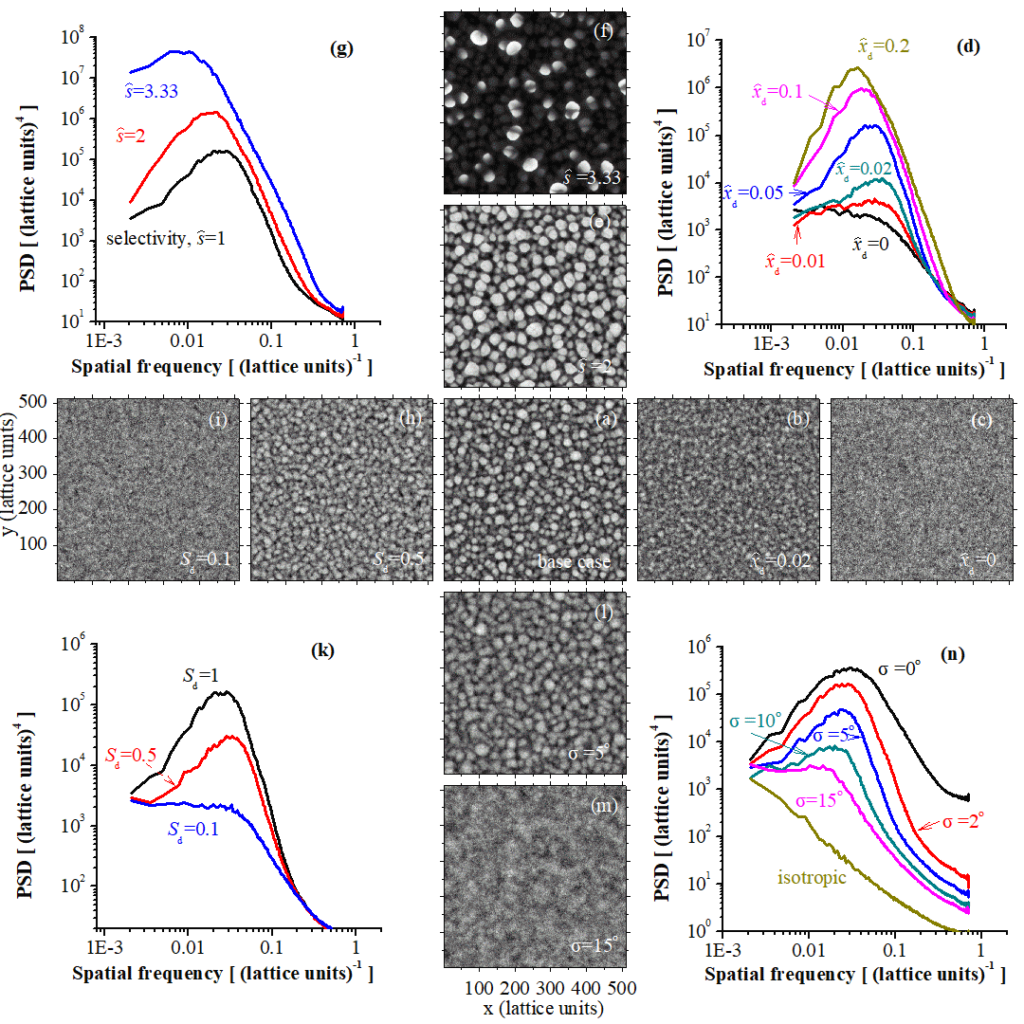

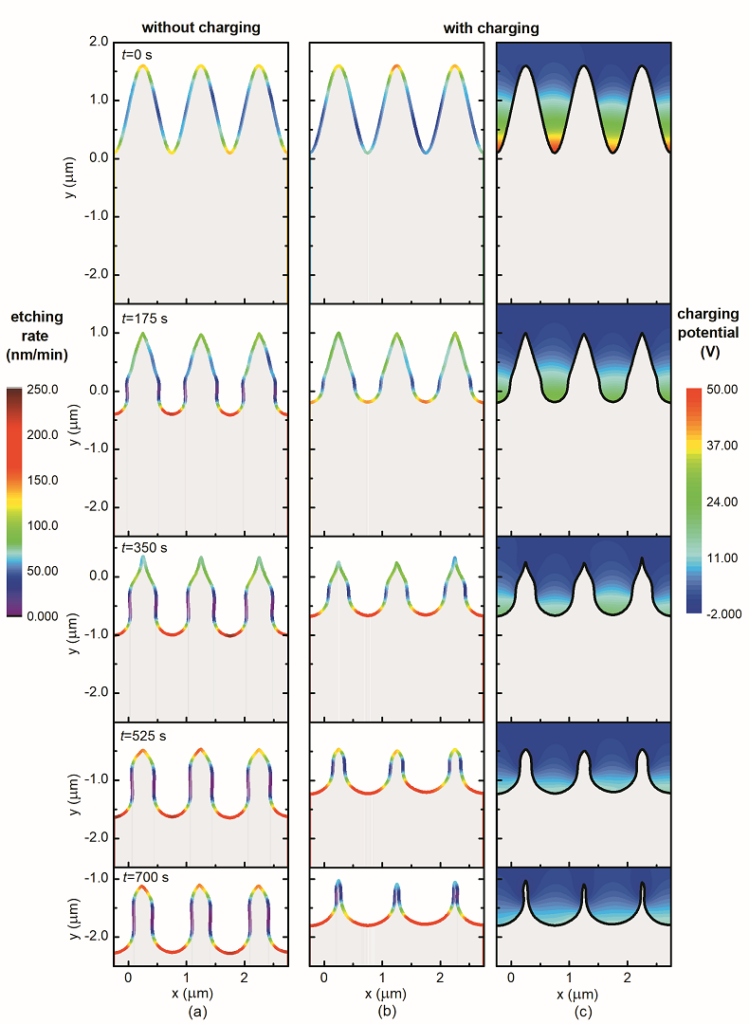

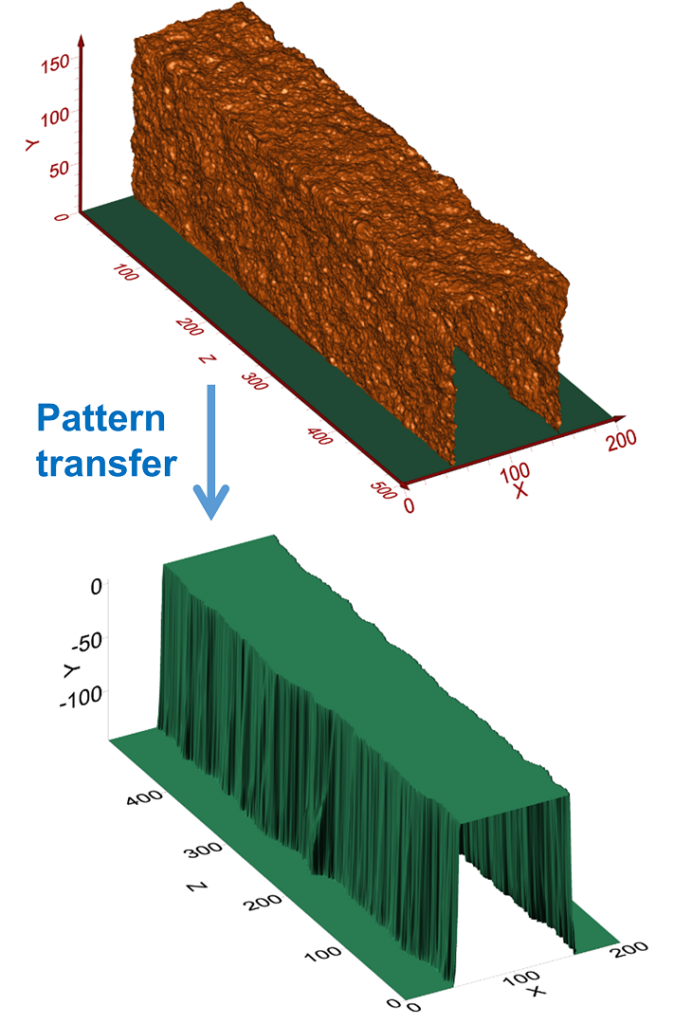

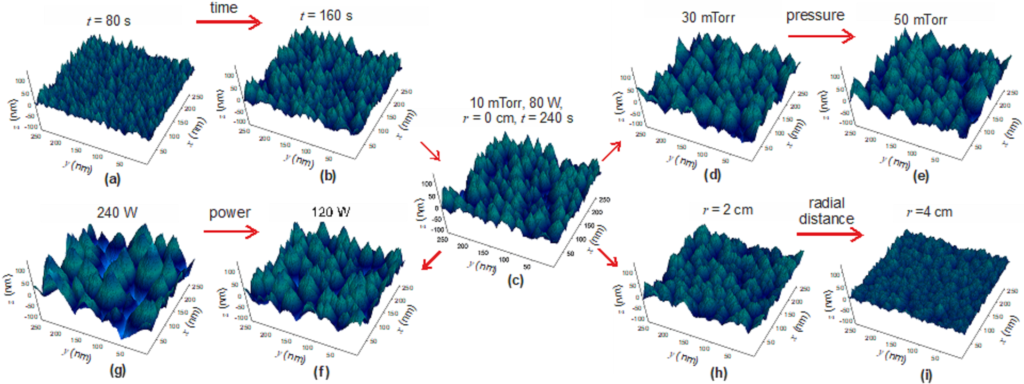

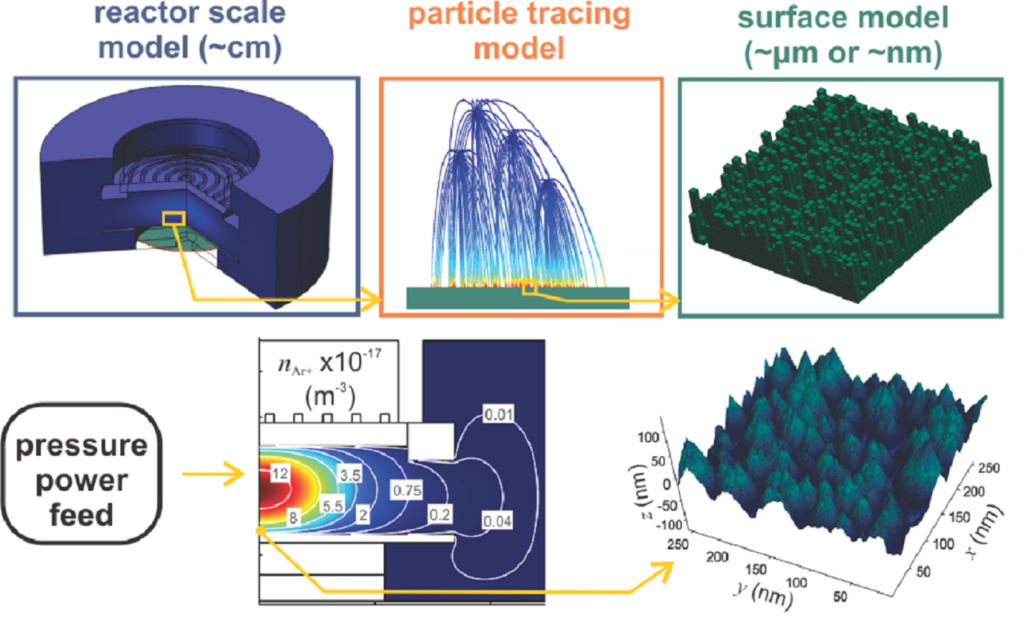

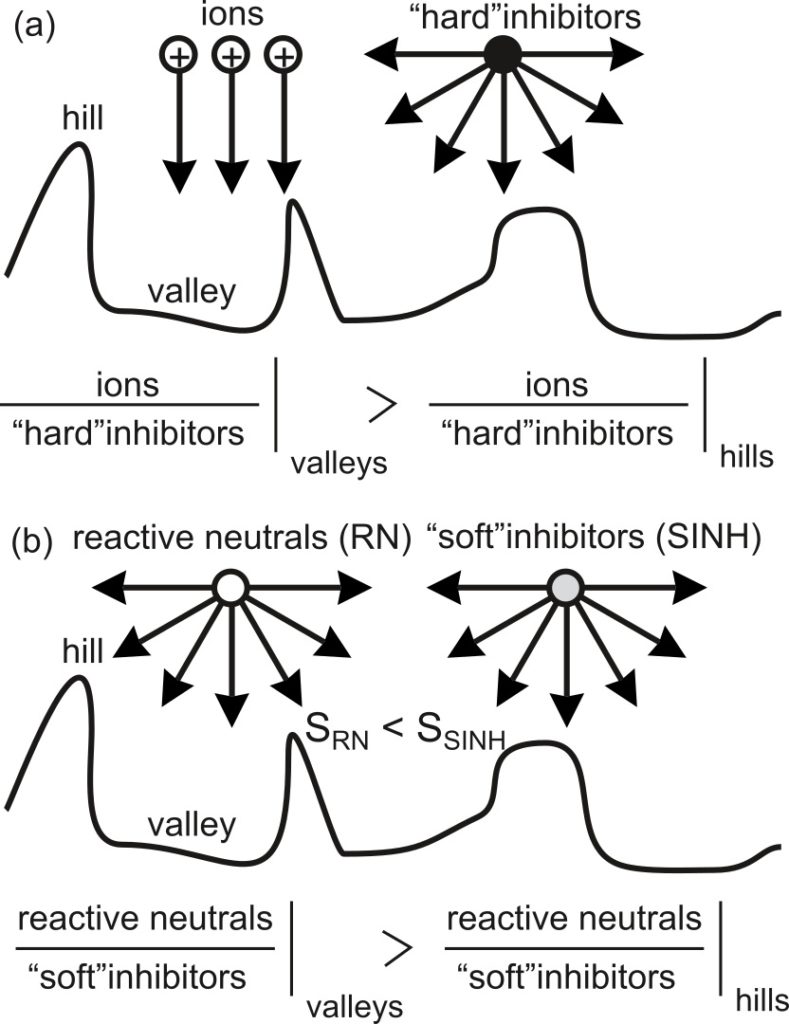

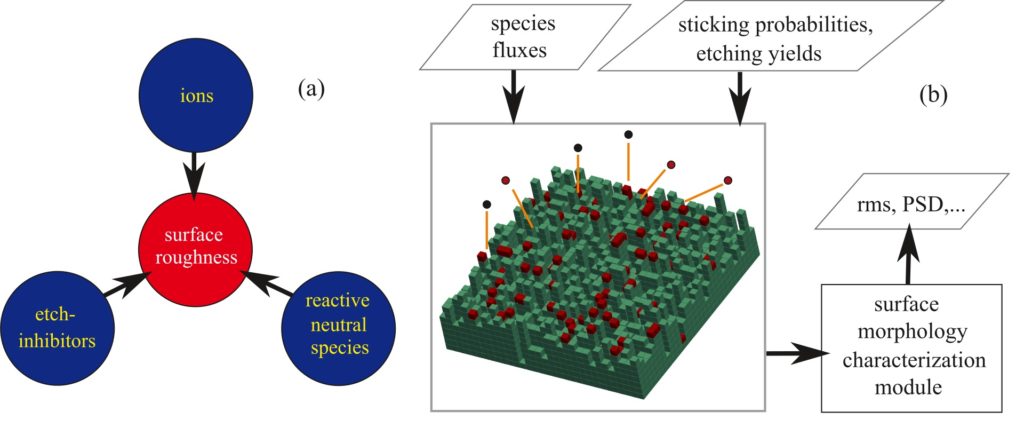

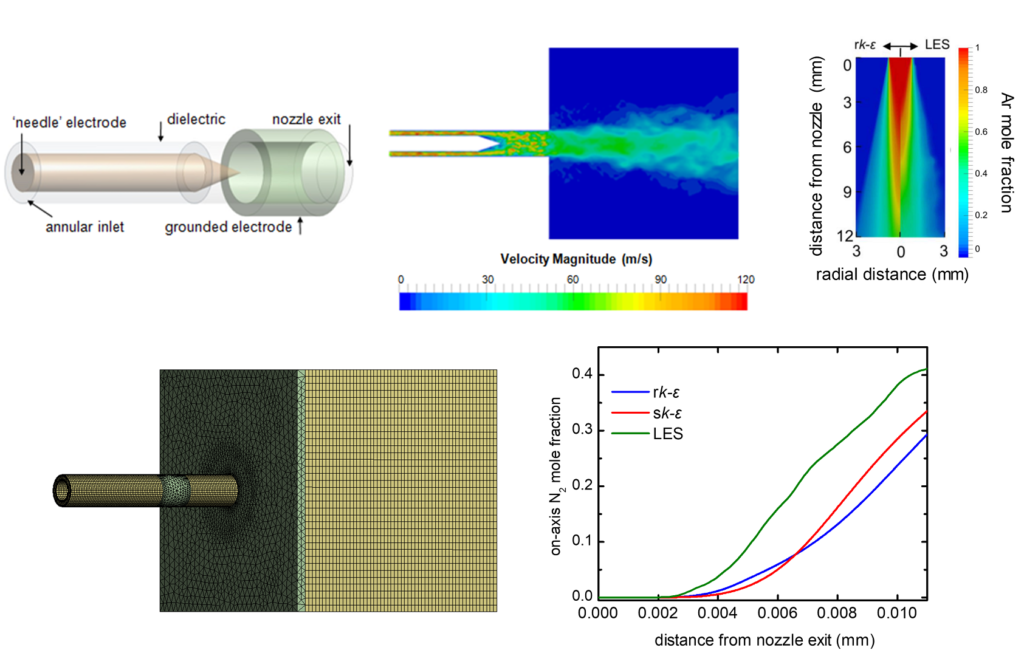

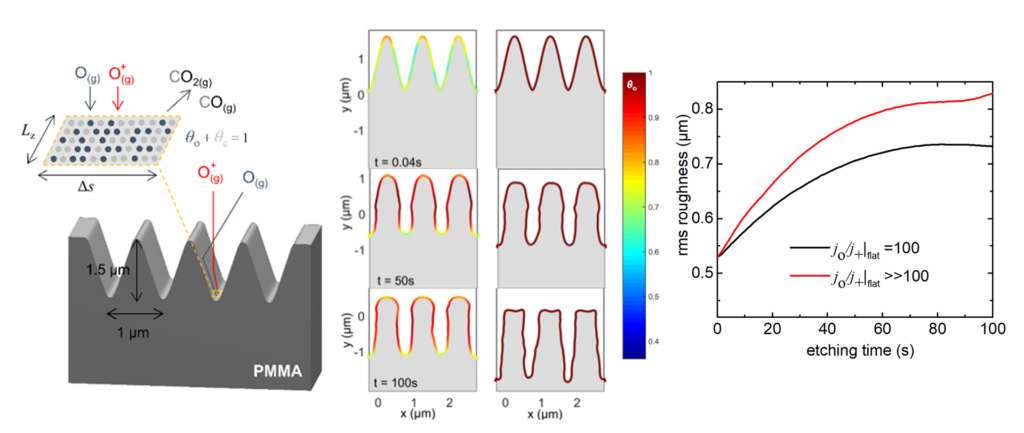

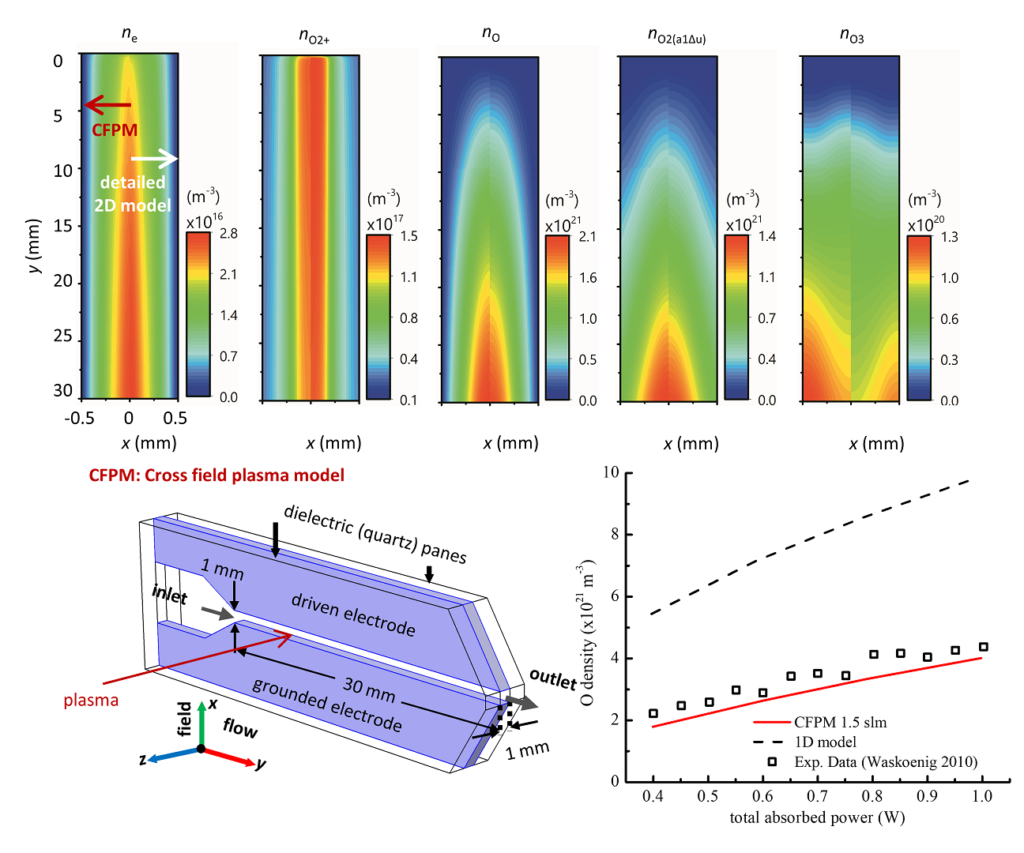

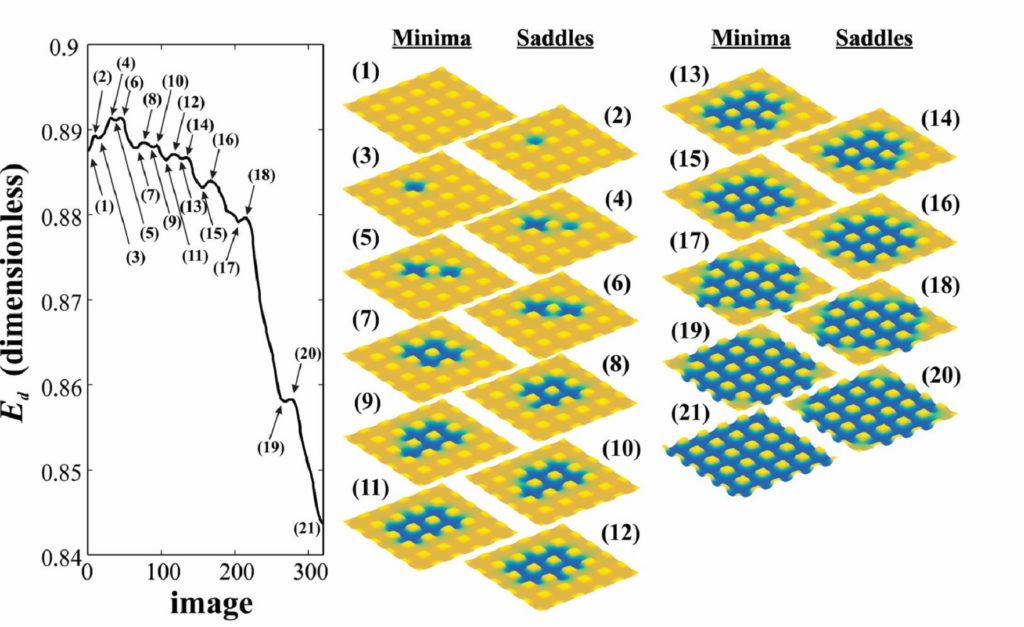

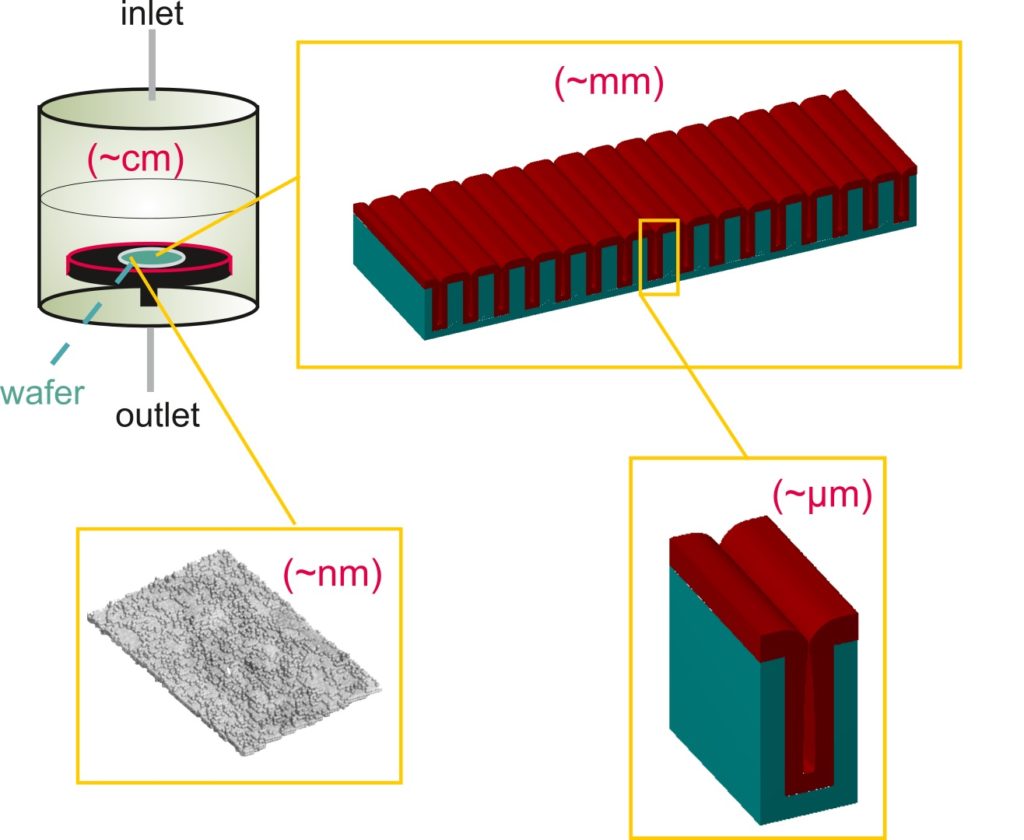

It focuses on plasma discharges and covers both low (<1-10 Pa) and atmospheric pressure processes. It deals with the bulk phase of the plasma (reactors) as well as the interaction of plasma with surfaces. It handles all spatial scales of the events taking place during plasma processing, from the order of centimeters of a plasma reactor or a plasma jet to the order of micrometers or nanometers on a) a plasma-wetted rough surface or b) a conventional trench in microelectronics. It addresses micro- and nano-electronics, engineering of functional surfaces, as well as alternative applications of plasma in agriculture and biomedicine.

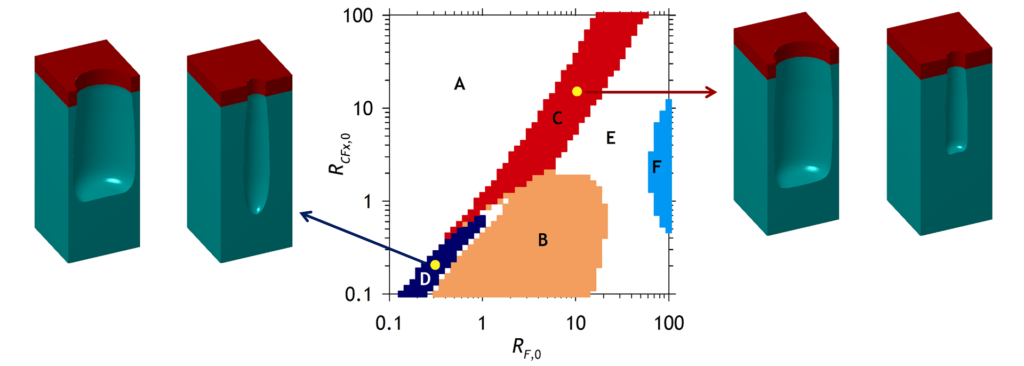

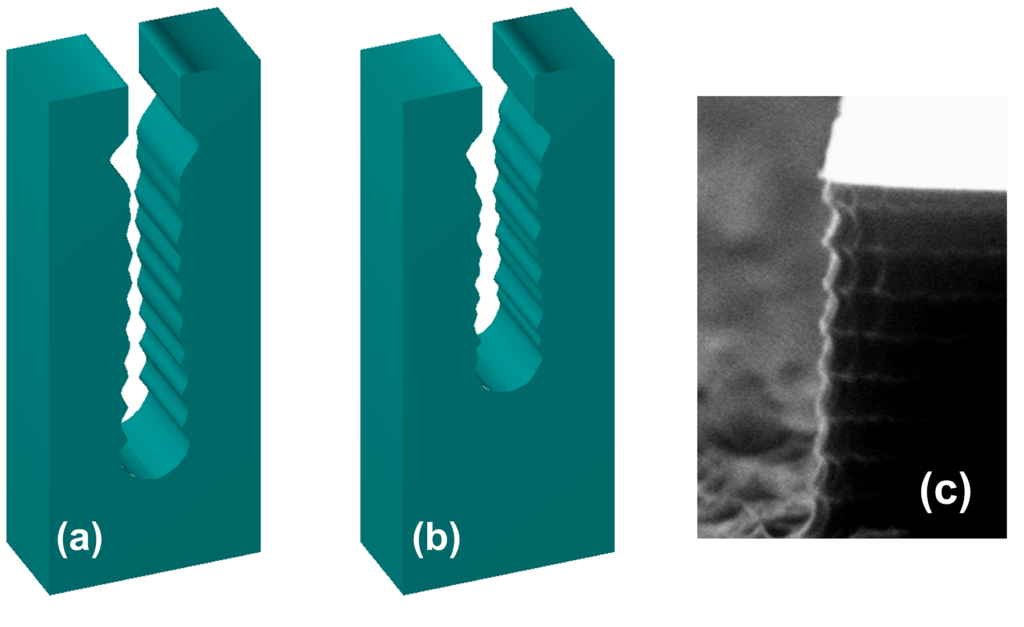

The aims are the investigation of mechanisms, process design, and the development of shortcut models or numerical methods for the reduction of the computational cost. Our tools are homemade, open source, and commercial code. The computational frameworks are usually hybrid, combining continuum and stochastic approaches. Besides the publications, our effort has yielded to two user-friendly software tools. The first for the study of chemical kinetics in the bulk plasma (www.plasma-r.com) and the second for the study of profile evolution of micro- and nano-trenches or holes during plasma etching (www.phietch.com).

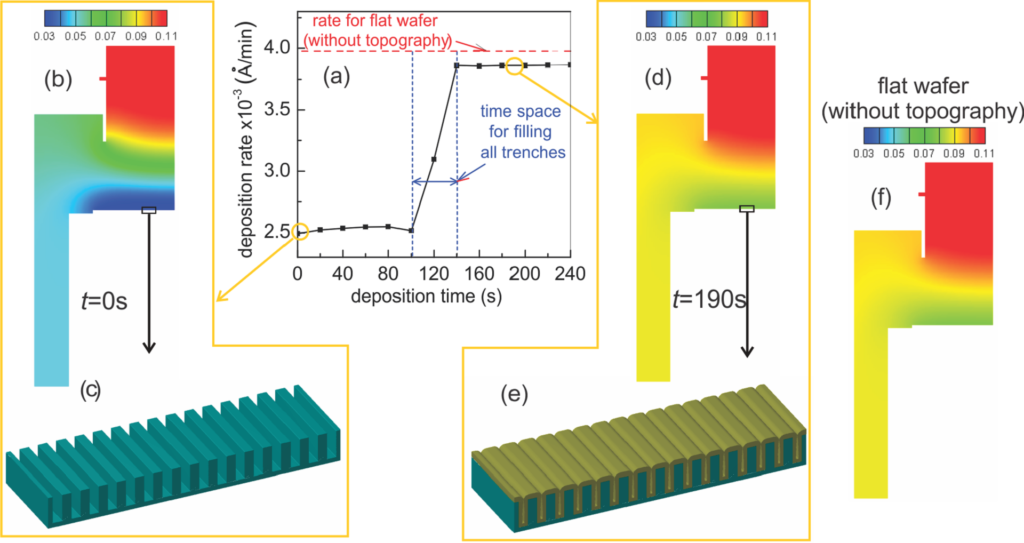

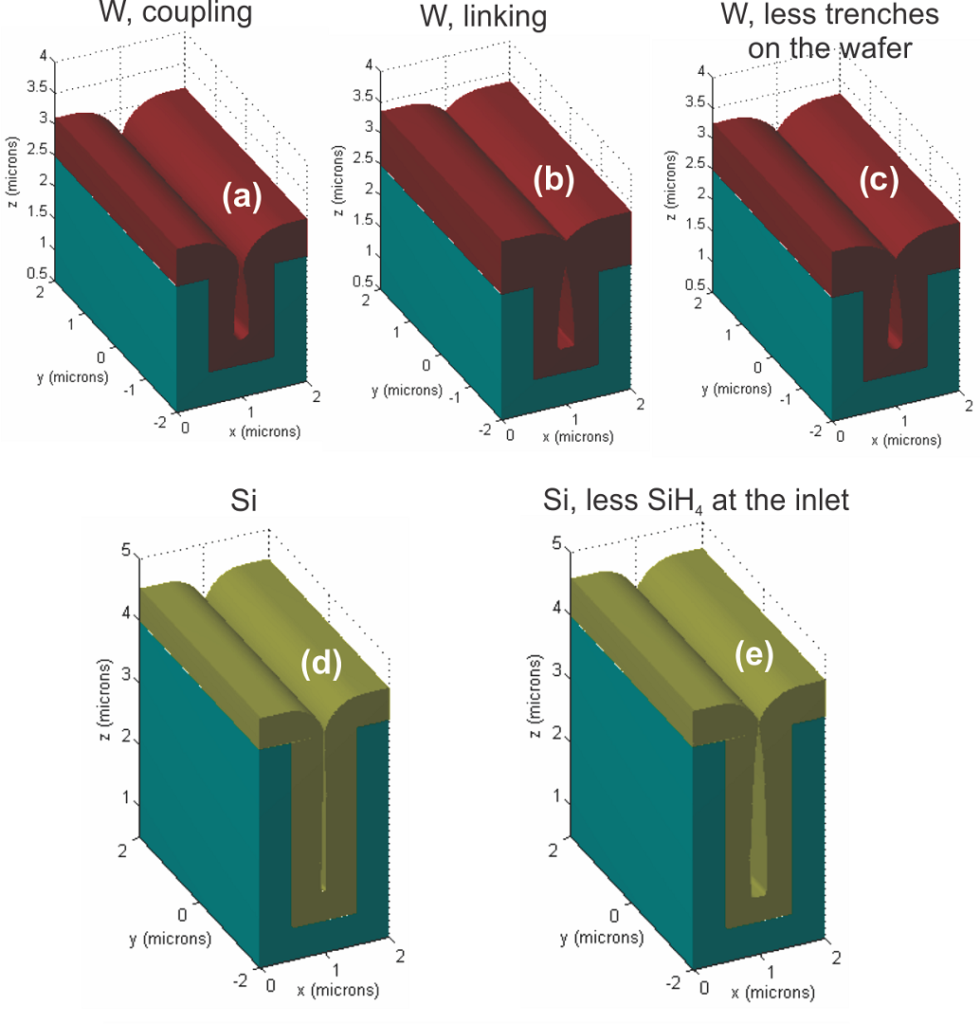

Besides plasma processing, chemical vapor deposition (CVD) has been also studied. The major aim is the investigation of the interaction between the microscale of the features (e.g., trenches) and/or the nanoscale of the deposited films and the macroscale of the CVD reactor. A hybrid multiscale modeling framework has been developed and parallel techniques have been utilized to reduce the computational cost.

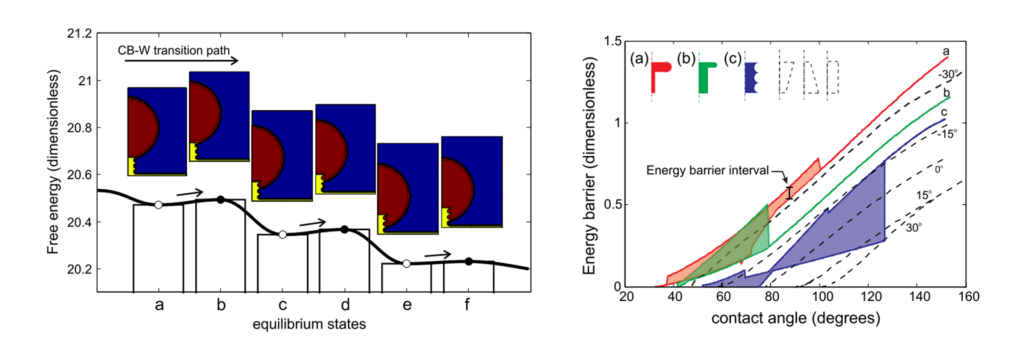

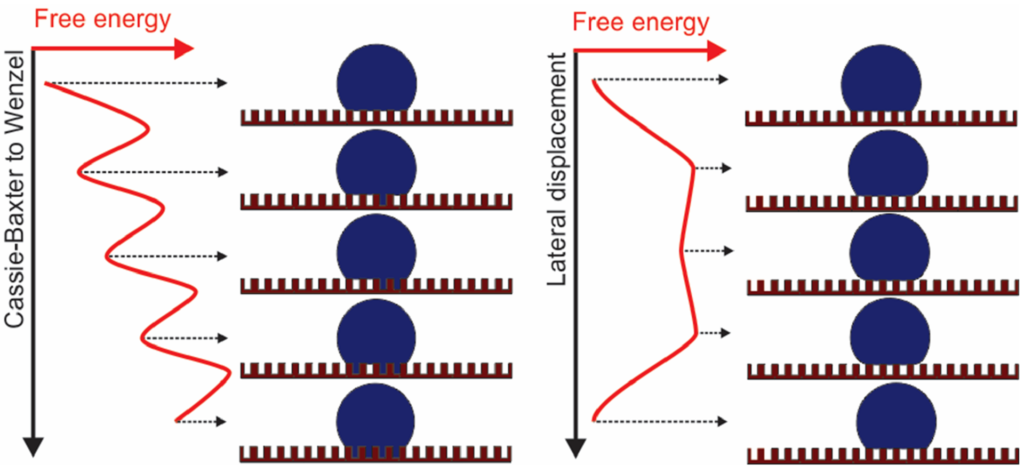

Besides fabrication processes, the wetting behavior and water condensation on surfaces has been investigated. In particular, the transition from partially wetted (Cassie-Baxter) state to the fully wetted (Wenzel) state, critical for the robustness of superhydrophobic surfaces, has been studied by calculating the energy barrier between these states. Additionally, the dropwise condensation on surfaces, critical for heat transfer and water harvesting applications, has been investigated through a thermal resistance model.

Infrastructure

The current infrastructure for numerical analysis and simulation is a computer cluster consisting of 11 workstations with a total of 316 cores and 1184 GB of RAM.

Categories of the activityThe activity on process (and phenomena) analysis and simulation can be categorized into 6 areas, namely, A) plasma reactors at low pressure, B) plasma etching of micro- and nanostructures, C) roughening of plasma-wetted surfaces, D) plasma reactors at atmospheric pressure, E) chemical vapor deposition of films in structures and open areas, and F) wetting and condensation on surfaces. The highlights of the research in each area can be found in the following list of key publications.