Water and Energy Harvesting Surfaces and Devices

A. Water harvesting and recycling

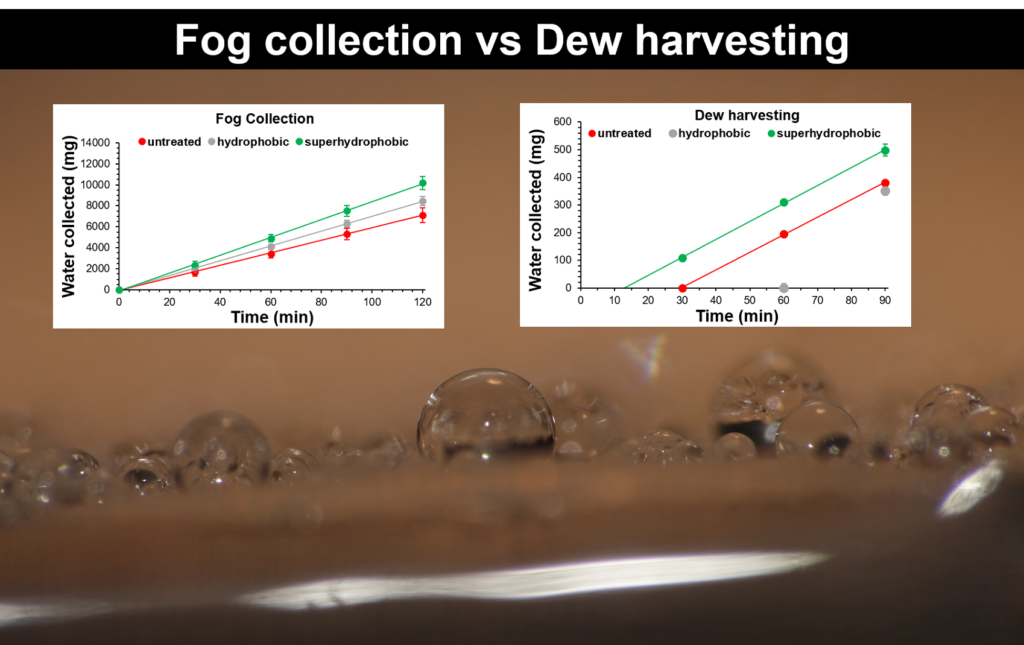

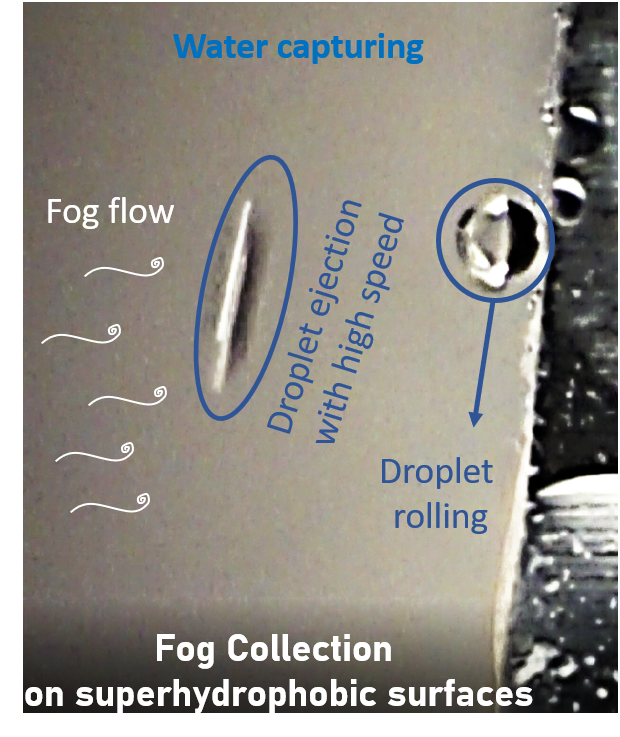

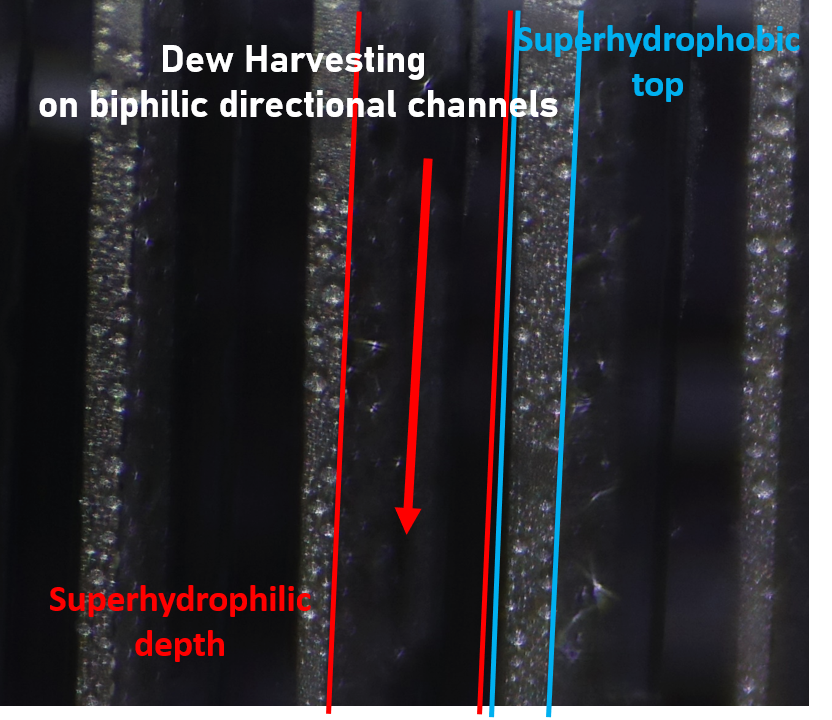

We are acutely aware of the escalating global challenges of water and energy scarcity, which are expected to worsen in the coming years. In response, we have initiated targeted efforts in water and energy harvesting, as well as water recycling. A central focus of our work is the development and application of superhydrophobic and biphilic surfaces to harvest atmospheric water—actively via condensation and passively via fog collection. These superwetting surfaces markedly enhance water collection efficiency. Moreover, we have systematically investigated the distinct performance characteristics of these surfaces under dew and fog harvesting conditions. In addition, we have improved the durability of both the surface texturing and coatings employed—an essential step toward the practical fabrication of robust superwetting surfaces.

Selected publications

- How different are fog collection and dew water harvesting on surfaces with different wetting behaviors? D. Nioras, K. Ellinas, V. Constantoudis, E. Gogolides, ACS Applied Materials & Interfaces 13 (40), 48322-48332

- Atmospheric water harvesting on micro-nanotextured biphilic surfaces, D. Nioras, K. Ellinas, E. Gogolides, ACS Applied Nano Materials 5 (8), 11334-11341

- Durable Surfaces of Both Wettability Extremes with Stable Dew Harvesting Performance During Liquid–Vapor-Phase Transitions, D. Nioras, E. Gogolides,K. Ellinas, Industrial & Engineering Chemistry Research 63 (48), 20872-20882

B. Energy Applications

Efficient power generation via dropwise condensation

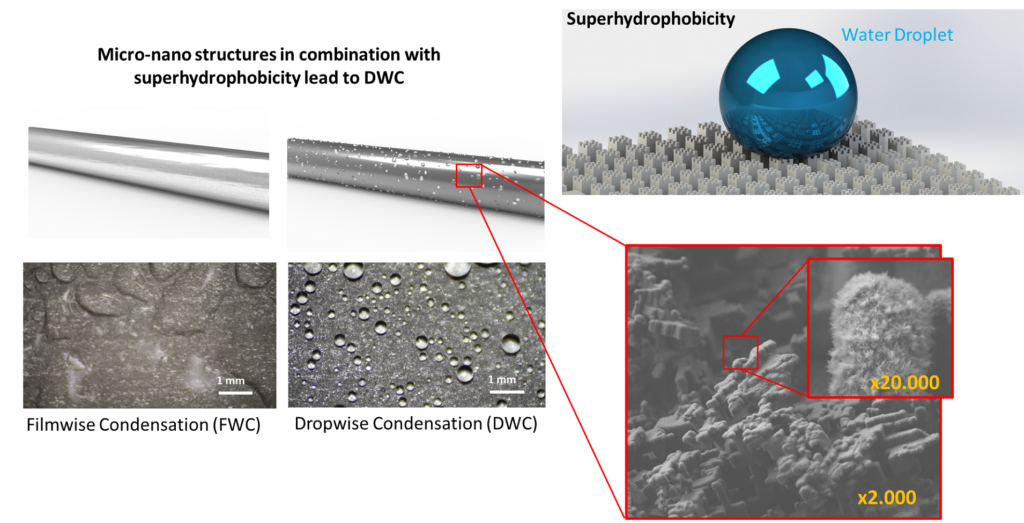

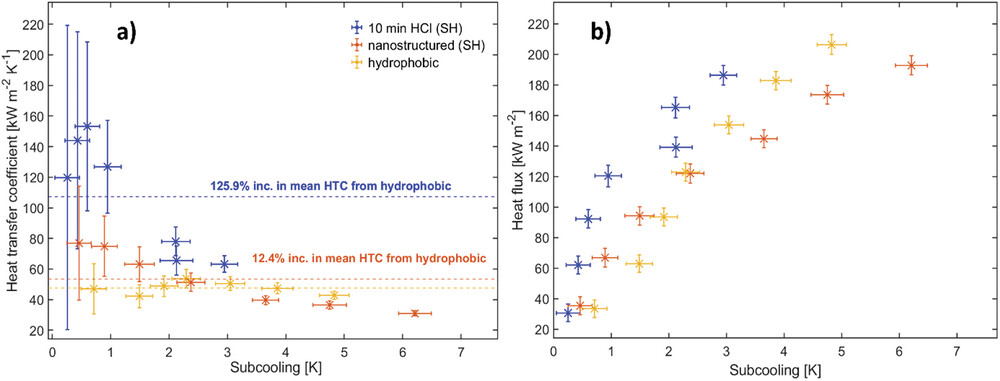

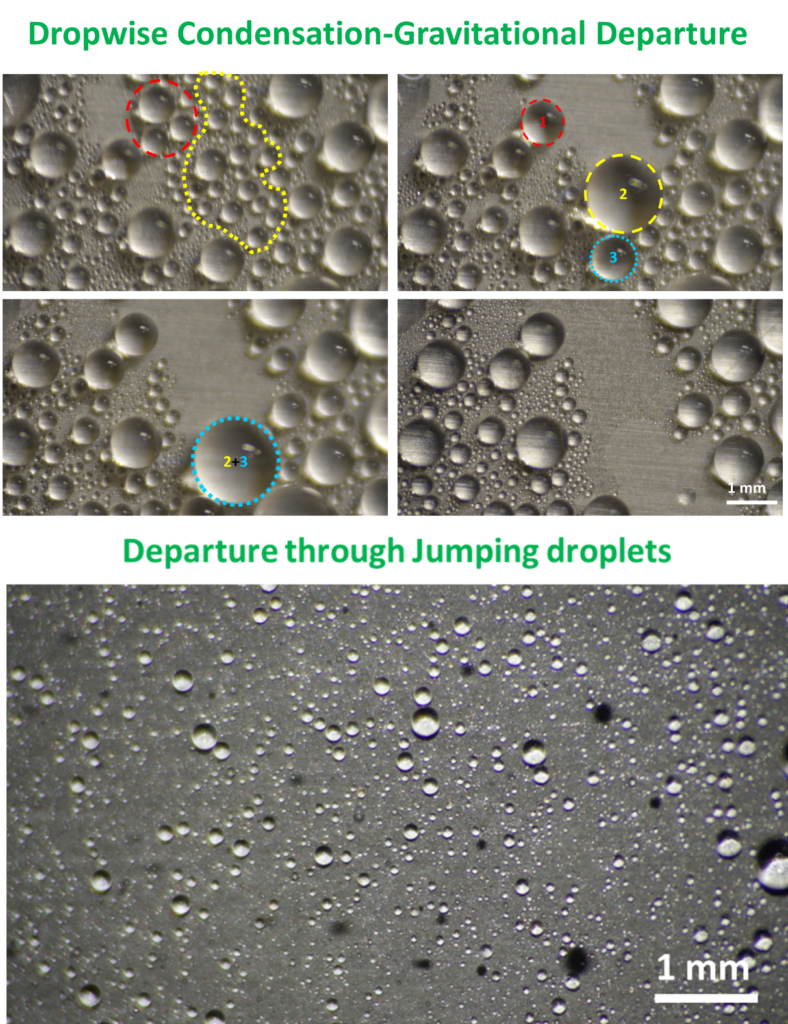

Condensation is crucial for many technologies involving heat transfer, such as steam-cycle power generation, water desalination, and air-conditioning systems. Typically, condensation on metallic surfaces forms a continuous liquid film that increases thermal resistance and reduces the area available for additional condensation. A more efficient way to enhance heat transfer is to force the steam to condense into distinct, mobile droplets that quickly shed from the surface. This condensation mode is known as dropwise condensation.

Water-repellent (superhydrophobic) surfaces help achieve dropwise condensation by making droplet shedding easier and faster. Such surfaces require specific micro- and nanostructures to minimize the droplet contact area, combined with low surface energy to reduce interactions between water and the surface.

In this work, we establish critical design parameters for these micro- and nanostructures, ensuring sustained dropwise condensation and improved heat transfer. Using these guidelines, we achieved a 2.3× improvement in heat transfer compared to flat hydrophobic surfaces and an order-of-magnitude enhancement over untreated metallic surfaces.

Publication: https://doi.org/10.1002/adfm.202306756

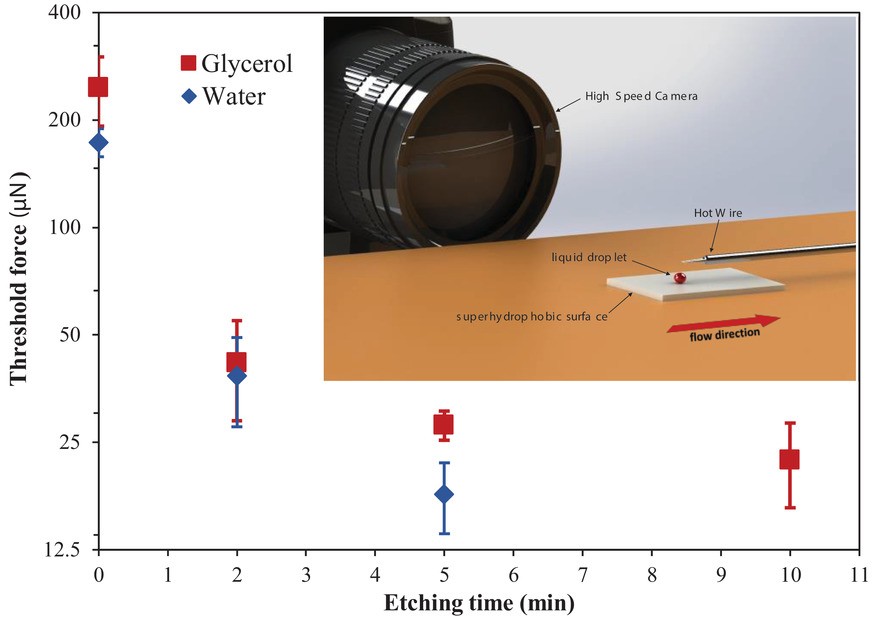

Friction and drag reduction

Superhydrophobic surfaces offer anti-frictional properties due to the entrapped air layer between their structures. We measured the interfacial friction between water and glycerol droplets inside a wind tunnel and showed that a superhydrophobic surface with contact angle higher than 150° and hysteresis angle of 1° reduces the interfacial friction down to 15 μN from the 175 μN measured on a hydrophobic surface.

Selected publications

- Panagiotis Sarkiris, Kosmas Ellinas, Dimitris Gkiolas, Dimitrios Mathioulakis, Evangelos Gogolides, Motion of Drops with Different Viscosities on Micro-Nanotextured Surfaces of Varying Topography and Wetting Properties, Advanced Functional Materials , 2019 [doi]

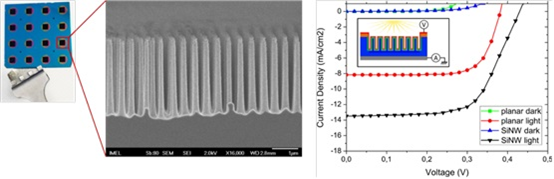

Solar energy harvesting

On the energy saving front we also use plasma etching to fabricate Silicon nanowire solar cells with axial or radial p-n junctions that show promise as cheaper and more efficient alternative solar cells. Below we show Silicon nanopillars fabricated with cryogenic etching with radial p-n junction used as photovoltaic devices. Similar work with axial p-n junctions has also been conducted. This activity has been hit by the global downfall of silicon solar cells, however, it has added a significant know how in our group and has been a model of collaboration with the plasma lab and the clean room facility of INN.

C. Superhydrophobic Membranes for enhanced water production and wastewater treatment

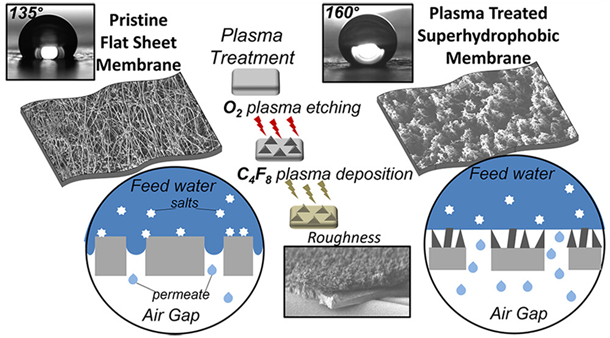

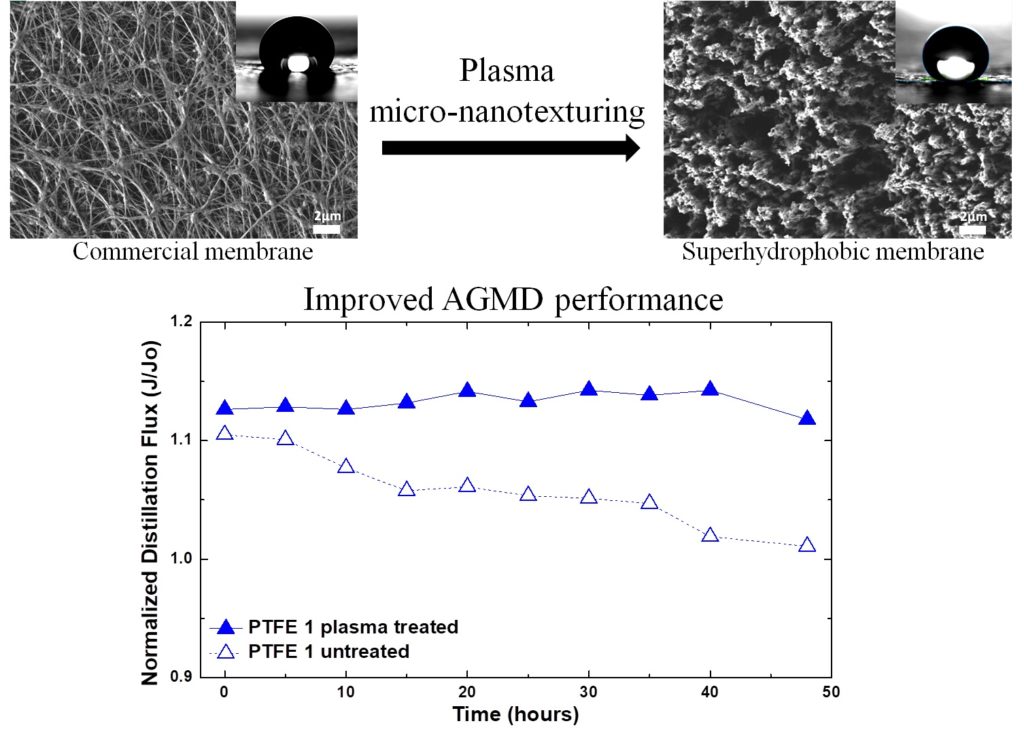

Superhydrophobicity has only recently become a requirement in membrane fabrication and modification. Superhydrophobic membranes have shown improved flux performance and scaling resistance in long-term membrane distillation (MD) operations compared to simply hydrophobic membranes. In the context of Harmonic project and Superclean project, we have introduced plasma micro- and nanotexturing followed by plasma deposition as a novel, dry, and green method for superhydrophobic membrane fabrication. Using plasma micro- and nanotexturing, commercial membranes, both hydrophobic and hydrophilic, are transformed to superhydrophobic featuring water static contact angles (WSCA) greater than 150° and contact angle hysteresis lower than 10°. To this direction, hydrophobic polytetrafluoro- ethylene (PTFE) and hydrophilic cellulose acetate (CA) membranes are transformed to superhydrophobic. The superhydrophobic PTFE membranes showed enhanced water flux in standard air gap membrane distillation and more stable performance compared to the commercial ones for at least 48 h continuous operation, with salt rejection >99.99%. Additionally, their performance and high salt rejection remained stable, when low surface tension solutions containing sodium dodecyl sulfate (SDS) and NaCl (down to 35 mN/m) were used, showcasing their antiwetting properties. The improved performance is attributed to superhydrophobicity and increased pore size after plasma micro- and nanotexturing. More importantly, CA membranes, which are initially unsuitable for MD due to their hydrophilic nature (WSCA ≈ 40°), showed excellent performance with stable flux and salt rejection >99.2% again for at least 48 h, demonstrating the effectiveness of the proposed method for wetting control in membranes regardless of their initial wetting properties. Additionally, the plasma treated membranes have also demonstrated superior anti-fouling properties when used against solutions containing Bovine Serum Albumin (BSA) with concentrations up to 3 g/L.

In the context of the Exercise project, the same technology has been applied to a new generation of green functional surfaces consisting of natural polymers, such as Bacterial cellulose (BC), which can replace typical polymers. The materials which will be developed will be used a) as antibacterial surfaces in domestic, health and other applications in order to reduce the extensive use of antibiotics causing the antimicrobial resistance and b) as superhydrophobic biomembranes for separation applications.

Selected publications

- Eleftherios Manouras, Dimosthenis Ioannou, Angelos Zeniou, Andreas Sapalidis, Evangelos Gogolides, Superhydrophobic and oleophobic Nylon, PES and PVDF membranes using plasma nanotexturing: Empowering membrane distillation and contributing to PFAS free hydrophobic membranes, Micro and Nano Engineering, Volume 24, 2024 [doi]

- Dimosthenis Ioannou, Andreas Sapalidis, Evangelos Gogolides, White Light Reflectance Spectroscopy as a novel and noninvasive method for in situ wetting monitoring in membrane distillation, Desalination, Volume 574, 2024, [doi]

- Dimosthenis Ioannou, Prexa Shah, Kosmas Ellinas, Michael Kappl, Andreas Sapalidis, Hans-Jürgen Butt, Evangelos Gogolides, Antifouling Plasma-Treated Membranes with Stable Superhydrophobic Properties for Membrane Distillation, ACS Applied Polymer Materials, Vol 5/Issue 12, 2023, [doi]

- Dimosthenis Ioannou, Youmin Hou, Prexa Shah, Kosmas Ellinas, Michael Kappl, Andreas Sapalidis, Vassilios Constantoudis, Hans-Jürgen Butt, Evangelos Gogolides, Plasma-Induced Superhydrophobicity as a Green Technology for Enhanced Air Gap Membrane Distillation, ACS Applied Materials & Interfaces, Vol 15/Issue 14, 2023, [doi]