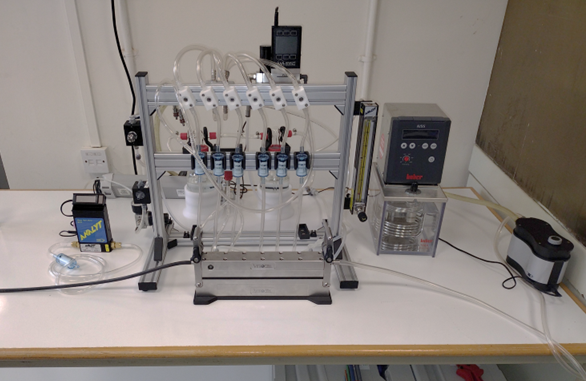

Air Liquid Interface Exposure system

Tool

Essentials, Vitrocell

Applications

- Inhalation toxicology / respiratory toxicology

- Identification of biomarkers

- Drug delivery / inhaled therapeutics

- Nanomaterial / nanoparticle toxicity & safety

- Air pollution / environmental exposure studies

- Smoking / e-cigarette / vaping product testing

- Comparative exposure modes / methodology development

- Dosimetry / deposition quantification studies

- Extended / long-term exposuresHigh-throughput / multi-well exposures

- Organotypic / 3D respiratory tissue models

- Mechanistic studies & molecular endpoints

Technical Specifications

| Parameter | Specification |

| Exposure principle | Air–liquid interface exposure; cells cultured on porous membranes with apical air exposure |

| Exposure type | Aerosols, gases, nanoparticles, or vaporized compounds |

| Exposure mode | Continuous flow, single droplet (Vitrocell Cloud), or dry powder deposition (Vitrocell PowderX) |

| Number of exposure wells | Typically 6 or 12 exposure positions per module (expandable) |

| Exposure uniformity | ±10 % across wells using calibrated flow and aerosol distribution systems |

| Gas flow control | Mass flow controllers with individual channel regulation |

| Humidity & temperature control | Maintained at 85–95 % RH, 37 °C for cell viability and reproducibility |

| CO₂ concentration | Typically 5 % adjustable via integrated gas mixing module |

| Deposition monitoring | Quartz Crystal Microbalance (QCM) or tracer-based dosimetry for real-time dose measurement |

| Exposure duration | Short-term (minutes) to long-term (up to 72 h continuous exposure) |

| Compatible cell culture inserts | Standard 6-, 12-, or 24-well Transwell® or ThinCert® inserts |

| Materials of construction | High-grade stainless steel and borosilicate glass; autoclavable components |

| Automation | Optional integration with Vitrocell Automated Exposure Station for sequential or extended studies |

| Data acquisition | Real-time measurement of flow, temperature, humidity, CO₂, and deposited dose |

Additional Tools

- VOC generator system

- Conditioning chamber

- Multi gas analyser Thermal desorption unit